Secondary Services add value to thermoformed parts.

Share:

Press Release Summary:

In-house painting facility runs 3 shifts so thermoformed part can be prepped, painted, and shipped within hours after it is formed. Screen Printing and Hot Stamping place logos, model designations, warnings, and other prominent information on thermoformed part. RFI and EMI shielding to interior of panels for electromechanical and electronic products is applied to exact specifications. Unlimited combination of surface finishes and textures are offered.

Original Press Release:

Painting, Screen Printing and Other Finishes Add Value to Thermoformed Parts: Applications Across Many Industries

Howes Cave, NY-Once a part has been thermoformed, it is often shipped to another facility to be painted, screen printed or stamped, or to have EMI or RFI shielding applied. Kintz Plastics Incorporated is one of the few thermoformers who performs all of these processes in house. This provides numerous benefits to the OEM purchasing that thermoformed part:

o Compressed Supply Chain: Having painting, screen printing, hot stamping or the application of EMI or RFI shielding-or complete assembly-provided by the thermoformer reduces the number of vendors required to produce a high-quality finished part.

o Reduced Cost: Kintz provides value-added services such as hot stamping, painting, screen printing and specialized finishes at a very attractive cost to the OEM because all those processes-plus thermoforming and assembly operations-take place at a central facility, reducing freight and handling costs.

o Faster Turnaround: By offering complete secondary services at one facility, Kintz Plastics is able to dramatically reduce the lead time to produce a finished part by eliminating the need to trans-ship parts to a paint shop, and then get into their production queue.

o Compressed Supply Chain: Thermoforming and performing value-added services at one location by one vendor, takes inventory out of the supply chain, further reducing costs.

o Better Quality: As an ISO 9001:2000 Registered company, quality is not just advertising hype. Kintz can insure quality and consistency because their quality system monitors all processes from thermoforming all the value-added services it provides.

The secondary services Kintz provides add value to the thermoformed parts it makes for its OEM partners is extensive:

o Both Solvent and Water-Based Paints: Kintz's in-house painting facility runs three shifts so a thermoformed part produced during any shift can be prepped, painted and shipped within hours after it is formed. Working with its OEM partners, the Kintz engineering staff (also staffed for two shifts) can recommend the painted finish that will be economical and durable, and meet the cosmetic needs of the customer.

o Screen Printing and Hot Stamping: Placing logos, model designations, warnings and other prominent information on a thermoformed part are excellent applications for screen printing and hot stamping. Exact colors and color combinations can be matched precisely, and the same run of thermoformed parts can be broken into smaller runs for screen printing when different art work or copy is required. Kintz has extensive experience and success printing on textured surfaces, a skill few screen printing facilities have mastered.

o Shielding: Kintz is a certified applicator of EMI/RFI shielding. The application of RFI and EMI shielding to the interior of panels for electromechanical and electronic products is critical to the finished product's success. RFI and EMI shielding must be thorough and consistent-and applied to the OEM's exact specifications to insure proper performance of the finished product-yet it must be economical for the OEM.

o Textured Finishes: As both the thermoformer, and the painter or screen printer, Kintz has the ability to offer an unlimited combination of surface finishes and textures for highly cosmetic parts. By controlling both the finish of the thermoformed part during the thermoforming process, and also controlling the painting or screen printing process, Kintz produces the exact color, feel, texture and finish the OEM requires.

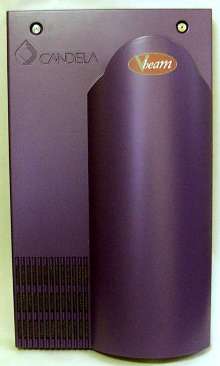

Industry Applications: Painting, screen printing, hot stamping and the application of RFI and EMI shielding have multiple applications for OEMs in many industries, from electro-medical, telecommunications, data storage and IT systems, to industrial equipment housings, material handling systems, HVACR products, and kiosks and POP displays.

Since 1976, Kintz Plastics Incorporated has partnered with manufacturers in many industries to produce parts, panels, housings, exteriors and components that add value to the OEM's products. Kintz has engineering coverage from 7:00 a.m. to 12:00 midnight (EST) to insure that every customer receives optimal value and world-class service and support. With over 100,000 square feet of manufacturing capacity, and the largest rotary thermoformer in the Eastern US-capable of producing thermoformed panels up to 9 by 13 feet with a 60-inch draw-Kintz is able to meet the heavy gauge vacuum forming, pressure forming and twin-sheet thermoforming needs of any OEM. For more information about Kintz Plastics, visit www.kintz.com or call (518) 296-8513.

QUESTIONS? Contact Alec Schibanoff at 732-463-3205 or alecs@ aasassociates.com.