Ring Drive suits indexing and rotary positioning applications.

Press Release Summary:

Merging Roller Pinion System technology with precision-grade bearing and gearhead, Precision Ring Drive can reach speeds up to 300 rpm and handle peak torques at all times. Unit offers indexing precision up to ±11 arc-sec with repeatability up to ±1.2 arc-sec. Supported by high-capacity cross-roller bearing, drive is rated for loads up to 1,575 kN, making it suited for demanding applications, including welding systems, medical products, robotics, automotive, and aerospace uses.

Original Press Release:

New Nexen Precision Ring Drive Delivers Precise, High-Speed Positioning for Indexing and Rotary Applications

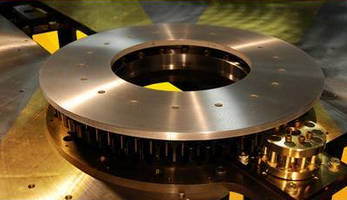

Vadnais Heights, MN - Nexen Group, Inc. introduces its new Precision Ring Drive (PRD), providing precision motion control for indexing and rotary positioning systems. Offering a unique combination of design and performance capabilities, the PRD meets positioning demands for next-generation machine designs.

By merging Nexen's innovative Roller Pinion System technology with a precision-grade bearing and gearhead, the PRD provides unparalleled performance for indexing and rotary positioning applications. With accelerations twice as high as similar indexing technologies, it can reach speeds up to 300 rpm, and unlike traditional cam-driven systems, the PRD can also handle peak torque inputs at all times. Capable of superior accuracy, it offers indexing precision up to ± 11 ArcSec with repeatability up to ± 1.2 ArcSec. Supported by a high-capacity cross-roller bearing, it's rated for loads up to 1575 kN, allowing it to accommodate demanding application requirements.

Containing a roller pinion system that is 99 percent efficient and a gearbox that performs at a 96 percent efficiency rating, the PRD meets current industry demands for higher performance capacities at lower energy costs. Its construction also provides continuously smooth motion, minimizing vibration during operation and resulting in less noise than conventional technologies. Also, with the pinion's lifespan of up to 60,000,000 revolutions, superior rigidity due to the preloaded cross-roller bearing, RPS and precision gearbox, the PRD provides greater durability and longevity over alternative solutions.

In addition to efficiency and durability, its design also minimizes maintenance requirements while enhancing flexibility. The elimination of oil baths allows the PRD to reduce labor and maintenance by not requiring time-consuming clean-ups. Further, the absence of oil baths also enables the drive to be mounted in any orientation. Plus, with the drive's large open center, it easily mounts to equipment while cabling can be filtered through the center, simplifying installation and improving mounting versatility.

With the PRD's performance capabilities, durability and versatility, it is an ideal solution for a wide range of demanding applications and industries, including:

o Welding Systems

o Positioning Systems

o Medical Products

o Robotics

o Automotive

o Aerospace

o Semiconductors

o Material Fabrications

Nexen Group, Inc is a leading manufacturer of precision motion control solutions including linear drive systems, precision rotary indexers, linear locking components and power transmission products including spring set brakes, tooth clutches and torque limiters for a wide variety of automation applications in the Aerospace, Robotics, Machine Tool, Automotive, Packaging, Material Handling and Medical Industries. For more information, contact Nexen Group, Inc., 560 Oak Grove Parkway, Vadnais Heights, MN 55127. Phone: 651-484-5900. Fax: 651-286-1099. E-mail: info@nexengroup.com. Website: www.nexengroup.com.