Power and Free Conveyor suits high-volume applications.

Press Release Summary:

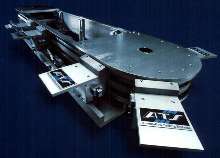

Suited for medical and automotive industries, Econotrak(TM) employs one belt that is continuously driven by variable-speed AC motor and VFD. Pallets engage belt by means of toothed pulley with integrated clutch, and tooling on leading edge of pallet disengages clutch when actuated. Cantilevered pallet design allows full multi-sided access to pallets and fixtures, and multi-axis operations can be performed right on pallets.

Original Press Release:

ATS Launches Innovative, More Economical Power & Free Conveyor-Econotrak(TM)

CAMBRIDGE. ON - A lean version of the highly successful ATS Supertrak(TM), the innovative, Econotrak(TM) power & free conveyor from ATS Automation Tooling Systems Inc. offers many of the same benefits, at lower cost - speed, simplicity, flexibility and long life. Econotrak(TM) offers performance and cost advantages over conventional belt- and chain-drive conveyors, particularly in high-volume applications such as those in the medical and automotive industries.

Like synchronous belt-drive conveyors, the Econotrak(TM)'s belt moves continuously, driven by a variable-speed AC motor and VFD, but that's where the similarity ends. Econotrak(TM)'s pallets engage the belt by means of a toothed pulley with an integrated clutch. Tooling on the leading edge of the pallet disengages the clutch when actuated.

Although Econotrak(TM) is competitive in price with other conveyors, it offers important advantages in speed, productivity and flexibility. Its cantilevered pallet design, borrowed from the ATS Supertrak(TM), allows full multi-sided access to pallets and fixtures, eliminating the need for lift & locates. Multi-axis operations can be performed right on the pallets, saving cycle time.

In addition, because the pallets are not in continuous contact with the belt, there's less load on the drive motors. This enables Econotrak(TM) to support more pallets, eliminating the need for multiple conveyor loops. Alternatively, it can reduce the number of drives required. Because wear is not applied to the belt during stops, as with other conveyors, belts and motors last longer. The result is lower maintenance costs. Expanding the system is easy on the budget too, since the system is made from low-cost, industry-standard components.

ATS has long been recognized as an innovation leader in the automation industry. In fact, not only has the company's technology often revolutionized the way products are manufactured, for years ATS has maintained a steadfast commitment to driving down the cost of automation by rewriting the performance/value equation. Econotrak(TM) is a prime example of how ATS is advancing 21st century automation to meet that commitment.

About ATS

ATS Automation Tooling Systems Inc. (www.atsautomation.com) is the industry's leading designer and producer of turnkey automated manufacturing and test systems. which are used primarily by multinational corporations operating in a variety of industries including: automotive, computer/electronics, healthcare and consumer products. The Company also makes precision components and subassemblies using its own custom-built manufacturing systems, process knowledge and automation technology. Through Photowatt International S.A., and Spheral Solar Power Inc., ATS is an emerging leader in the rapidly growing market for solar energy cells and modules. ATS employs approximately 3,500 people at 25 facilities in Canada, the United States, Europe and Asia-Pacific. The Company's shares are traded on the Toronto Stock Exchange under the symbol ATA.

For more information, contact:

Jim Beretta

Marketing Manager

ATS Automation Tooling Systems, Inc.

Box 32100 Preston Center

Cambridge, ON

Canada N3H 5M2

Phone: 519-653-6500

Fax: 519-650-6677

e-mail: info@atsautomation.com