Polyurethane Insulation Blocks offer alternative to wood.

Press Release Summary:

Providing thermal isolation while supporting heavy structural loads, LAST-A-FOAM® R-9300 Continuous Insulation Blocks extend insulation from below ground to roof of industrial and cold-storage buildings. Blocks are made of high-density rigid cellular polyurethane with closed-cell structure that is inert and prevents moisture absorption. Combination of compressive strength with minimal deflection and optimized thermal insulation values minimizes thermal bridging through adjoining materials.

Original Press Release:

General Plastics Expands Line of Polyurethane Continuous Insulation Blocks

New applications for wood-alternative thermal isolation blocks help extend structural insulation from below ground to the building roof

TACOMA, Wash. – Polyurethane innovator General Plastics Manufacturing Company has added new products to its premier LAST-A-FOAM® R-9300 Continuous Insulation Block Series. Addressing the need for thermal isolation while supporting heavy structural loads, the company’s expanded thermal block offerings extend a building insulation envelope from the roof to the foundation.

“We developed these new products in response to construction industry customers looking for comprehensive solutions to applications requiring thermal isolation,” explained President Bruce Lind. “Beyond our thermal column-bearing and floor reinforcement blocks, we now offer a full range of custom-cut insulating polyurethane blocks that outperform other materials.”

As shown in this YouTube video, the LAST-A-FOAM® R-9300 Continuous Insulation Block Series for industrial and cold-storage buildings now spans the following products and applications:

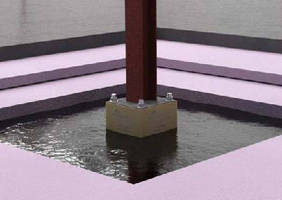

- Structural Thermal Isolation Column Block – designed to support heavy structural loads while maintaining thermal control within building interiors

- Precast/Tilt-Up Concrete Wall Panel Block for Load-Bearing Walls – prevents thermal energy transfer between the building and ground when installed under precast, tilt-up and brick/block walls

- LAST-A-FOAM® R-9320 IMP Thermal Floor Reinforcement Block – cost-effectively supports shelving and provides a thermal break within floor panels of insulated walk-in coolers and freezers

- Tank Isolation Protection Block – reduces condensation by thermally isolating chiller equipment from its supporting structure

- Canopy/Mansard Support Block – creates a thermal barrier for metal canopy or mansard supports at structural penetrations

- Roof Equipment Support Block – supports HVAC and other heavy equipment on building roofs while preventing radiant heat transfer to the building interior

- Perimeter Fall-Protection Block – serves as a key component of a commercial or industrial roof safety system

Proven thermal solutions outperform other materials

General Plastics’ Continuous Insulation Blocks are made of high-density rigid cellular polyurethane material. The foam’s closed-cell structure is inert and prevents absorption of moisture, so it does not rot or dissolve in subgrade applications, or promote corrosion of steel components. These construction blocks combine high compressive strength with minimal deflection and extraordinary thermal insulation values, reducing thermal bridging through adjoining materials. Their proven energy efficiency and durability make these thermal insulating blocks a cost-effective investment for long-term applications.

In addition to offering a full-building insulation envelope, LAST-A-FOAM® R-9300 Continuous Insulation Blocks arrive on-site ready to install. Blocks are custom manufactured to specific job requirements and can be predrilled with anchor-bolt holes.

“Through our partner CSI, customers will find a full range of high-quality insulated construction solutions that extend from below ground to the roof. They will also appreciate CSI’s technical expertise and responsive service in helping them choose, spec and use the right LAST-A-FOAM® 9300 Continuous Insulation Blocks for their specific application and project,” Lind added.

About General Plastics Manufacturing Company

Tacoma, Washington-based General Plastics has been a leading innovator in the plastics industry for more than 70 years. The company develops and manufactures rigid and flexible polyurethane foam products, which include its signature LAST-A-FOAM® brand series and build-to-print composite parts. Through its network of distributors, General Plastics exports products to 25-plus countries for the aerospace and defense, nuclear containment, composite core, prototype and modeling, construction, dimensional signage, testing, marine, and renewable energies industries. General Plastics is certified to ISO 9001:2008/AS9100C and meets such demanding quality systems as NQA-1, Mil-I-45208A and Boeing Company D6-82479. Visit www.generalplastics.com.

About CSI of Virginia, Inc.

Based in Richmond, Virginia, CSI of Virginia is a partnership of companies with sales offices strategically positioned throughout the United States. It is the exclusive distributor of premium products for commercial, industrial and cold-storage facilities, which range from walk-in boxes to 500,000-square-foot refrigerated warehouses, and from automobile dealerships to aircraft manufacturing facilities. Visit http://www.csiinc.org.