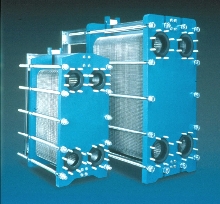

Plate Heat Exchangers lock together for tight seal.

Press Release Summary:

Plate Exchangers use less floor space and weigh less than conventional shell-and-tube heat exchangers. They use less surface area to transfer same heat. Plates are pressed in patterns that are best suited to optimizing performance of each individual system. Interlocking plates have locking lip that secures connection between plates and keeps them precisely aligned and tightly sealed even at high working pressures.

Plate Exchangers use less floor space and weigh less than conventional shell-and-tube heat exchangers. They use less surface area to transfer same heat. Plates are pressed in patterns that are best suited to optimizing performance of each individual system. Interlocking plates have locking lip that secures connection between plates and keeps them precisely aligned and tightly sealed even at high working pressures. Original Press Release:

New Calmac Plate Heat Exchangers High Efficiency, Low Maintenance, Long Life

Englewood, NJ -- For over 50 years, one company has continuously pioneered heating and air conditioning solutions. Today, Calmac Manufacturing Corporation, a world leader in Thermal Energy Storage (TES) products, has brought their engineering expertise to a new generation of Plate Heat Exchangers.

Like all Calmac products, the new Plate Heat Exchangers are designed for optimal performance. Stainless steel plates with densely-packed surface areas provide superior thermal efficiency. In fact, Calmac Heat Exchangers use up to 80% less floor space and often weigh 10 times less than shell-and-tube exchangers. Additionally, they use less surface area to transfer the same heat, which makes them easier, safer, faster, more efficient and far more economical to ship, handle, install and use.

A wide variety of plate sizes enables Calmac to provide the maximum economy for any size application. Plates are pressed in the patterns that are best suited to optimizing the performance of each individual system. It is this ability to combine the right plate geometry and patterns, along with superior connections, that gives Calmac products their performance advantage. The unique interlocking plate design, exclusive to Calmac Heat Exchangers, features a special locking lip which secures the connection between plates and keeps them precisely aligned and tightly sealed even at high working pressures.

Other features of the new Calmac Plate Exchangers include Close Temperature Capabilities (true countercurrent flow, which directs the two media in opposite directions across the plate resulting in maximum temperature difference and minimum heat transfer surface requirements. Temperature approaches as close as 1° - 2°F can be obtained); No Cross-Contamination (hot and cold media circuits are individually gasketed with the area in between vented to the atmosphere, assuring the integrity of both circuits); Minimum Fouling (continual scrubbing action all but eliminates the need for frequent cleanings); and Ease of Maintenance.