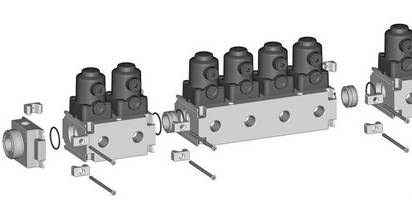

Plastic Multi-Port Valve Blocks are customizable and expandable.

Press Release Summary:

Promoting compact and customized implementation of valve interfaces in piping systems, multi-port valve blocks can integrate such functions as blending, diverting, channelling, draining, or supplying various liquids (including chemicals). Dosing functions can also be implemented with multi-port valve blocks. Combination of valve functions in one plastic block helps conserve space, while number of individual components helps minimize installation time.

Original Press Release:

Compact, Quickly Assembled, Cost-Effective: Extendable Plastic Blocks

With GEMÜ multi-port valve blocks made of durable plastics, valve interfaces in piping systems can be implemented in an extremely compact and customized manner.

For plant designers, this solution offers numerous advantages, such as the space savings achieved through the combination of valve functions in a single plastic block, the shorter installation time due to the significant reduction in the number of individual components, the increased plant reliability due to the reduction in bonded or welded points and reduced operating costs.

In a customized valve block design, GEMÜ can integrate a very wide variety of functions such as blending, diverting, channelling, draining or supplying a very wide variety of liquids (including chemicals). Dosing functions can also be implemented with multi-port valve blocks.

Numerous manufacturers offer process plants in different versions and/or want to keep open the opportunity for subsequent extension of the plant.

The "extendable multi-port valve blocks" were developed based on these applications and in partnership with customers. The concept provides OEMs with a customized modular system which can be adapted to individual requirements.

The new concept can cover a majority of possible variants with just a few basic versions. Within seconds and without additional piping, adhesive bonding or welding, these basic blocks can be connected to produce an extended multi-port valve block. Subsequent modifications to the process plant which are requested by the plant operator can also be implemented quickly and easily. This offers genuine added value to suppliers and operators alike.

The product can be used cost effectively in plants of the chemical industry and environmental chemistry sector, in surface finishing, coating and electroplating plants, municipal and industrial water treatment plants and other areas of use

GEMÜ Background Information

GEMÃœ is one of the world’s leading manufacturers of valves, measurement and control systems. Since 1964, this globally focused, independent family-owned enterprise has established itself in important industrial sectors thanks to its innovative products and customised solutions for process media control. GEMÃœ is the world market leader for sterile valve applications in the pharmaceutical and biotechnology industries.

Today, the GEMÜ Group employs 720 employees in Germany and more than 1,300 employees worldwide. Manufacturing is carried out in six production companies in Germany, Switzerland, China, Brazil, France and the USA. From Germany we coordinate global marketing with 20 subsidiaries. With a large distributor network in 53 countries, the GEMÜ group is present on all five continents. GEMÜ will continue to establish itself in future markets with its international growth strategy. This will be achieved by the opening of a new Production and Logistics Centre in Germany in 2013. In 2012 already, production capacities were greatly expanded in Switzerland.

A broad based modular system and adapted automation components mean that predefined standard products and customised solutions can be combined to make over 400,000 product versions.

Further information can be found at www.gemu-group.com.