Overmolded Lead Frames create one integrated part.

Press Release Summary:

Enabling OEMs to simplify designs by using single stamped piece, Overmolded Lead Frames can be made to customer specification using wide variety of stamped metals and plastics. Units are developed using rapid prototyping with 3D solid modeling analysis, and can be manufactured from virtually any alloy including medical grade, titanium, platinum, stainless, and copper alloys. Lead frames are supplied on reels for integration with molding processes.

Original Press Release:

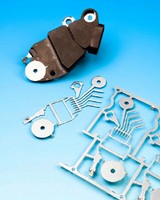

Overmolded Lead Frames Create One Integrated Rugged Part

Custom fabricated electrical components that feature overmolded lead frames to create a single integrated part which is rugged, easier to assemble, and has one SKU are available from ETCO Incorporated of Warwick, Rhode Island.

ETCO Overmolded Custom Lead Frames combine technologies to produce one part that offers superior flex and strain relief, higher reliability, assembly efficiency, and reduced costs. Enabling OEMs to simplify designs by using a single stamped piece, these custom overmolded lead frames can be made to customer specification using a wide variety of stamped metals and plastics.

Developed using rapid proto-typing with 3-D solid modeling analysis, ETCO Overmolded Custom Lead Frames can be manufactured from virtually any alloy including medical grade, titanium, platinum, stainless, and copper alloys. The lead frames are supplied on reels for integration with molding processes that can incorporate a wide range of engineering plastics.

ETCO Overmolded Custom Lead Frames are priced according to design, materials, and quantity; typically suited for 500,000 parts/yr. production quantities. Literature and price quotations are provided upon request.

For more information contact:

ETCO Incorporated

John J. Macaluso, VP Marketing

25 Bellows St.

Warwick, RI 02888

(401) 467-2400 FAX (401) 941-2453

e-mail: jmacaluso@etco.com

www.etco.com