Optical Measurement System uses image analysis algorithms.

Share:

Press Release Summary:

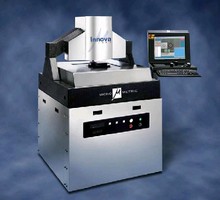

Based on sound metrology principles, Innova provides point-to-point and field-of-view non-contact measurements of semiconductor, optoelectronic, and MEMS devices. It delivers FOV measurement down to 0.5 µm with measurement accuracy of 0.010 µm. Providing 200 x 200 mm XY stage travel, system has granite structural components and vibration isolation support stand for stability. Additional features include autofocus, auto illumination, and automatic wafer handler.

Original Press Release:

Innova Measurement System Is Ready For Nanotechnology

San Jose, CA USA - June 2006 - Micro-Metric, an industry leader in ultra high-precision dimensional metrology, announces the Innova optical measurement system for highest resolution and accuracy industrial metrology applications. Innova delivers exceptionally accurate point-to-point (PTP) and field-of-view (FOV) non-contact measurements of semiconductor, optoelectronic, and MEMS devices. Based on sound metrology principles and using powerful image analysis algorithms, Innova provides FOV measurement down to 0.5 µm with measurement accuracy of 0.010 µm (10 nm).

Micro-Metric will display this versatile system September 6-13, 2006, in Booth D-4618 at the International Manufacturing Technology Show (IMTS) in Chicago, IL.

Innova features 200 mm x 200 mm of high-precision XY stage travel. To ensure optimum stability, it has granite structural components and a vibration isolation support stand. Suitable for manual single measurements, it can also be programmed for fully automated sequences of measurements. Sub-pixel interpolations of intensity transitions allow sub-micron linewidth measurements.

The Innova system offers several key features for superior nanoscale measurement:

Autofocus precisely positions the microscope at the best focus point by mathematically analyzing edge sharpness through a series of focus positions.

Auto illumination automatically adjusts light intensity for best signal-to-noise ratio, providing maximum measurement repeatability.

Automatic wafer handler with prealigner (optional) allows wafers to be loaded from and returned to any slot in either of two cassettes. The prealigner can align to flats of all sizes, or notches. The system automatically deletes alignment marks, and performs measurements without operator assistance.

About Micro-Metric

Founded in 1979, Micro-Metric produces high-accuracy, non-contact measurement and assembly systems. Products include automated and manual critical dimension measurement systems, non-contact coordinate measuring systems, and micro-positioning assembly systems. Based in San Jose, CA, Micro-Metric's global customer base includes most of the leading manufacturers of semiconductors, magnetic data storage systems, and fiber optics. Micro-Metric is a supplier to the National Institute of Standards and Technology (NIST). The company can be reached at +1 408-452-8505, by e-mail at info@micro-metric.com, or online at www.micro-metric.com.

Micro-Metric is part of Quality Vision International, Inc. (QVI), of Rochester, NY, the world's largest vision metrology company, with corporate facilities located in the United States, Germany, Singapore, India, and China. QVI can be reached at +1 585-544-0450, by e-mail at info@qvii.com, or online at www.qvii.com.