Measurement Amplifier optimizes press-fit accuracy.

Press Release Summary:

Model MP85 facilitates 2-channel monitoring by checking 2 inter-related signals. Almost any sensor can be connected to amplifier, including strain gage sensors, inductive or incremental transmitters, and SSI transducers. Model MP85 uses algorithms for curve evaluation with max of 9 predefined windows for each curve, or 1 master curve with envelope as evaluation criteria. Digital I/Os save statistics on component quality, either on PC or internal MMC card.

Model MP85 facilitates 2-channel monitoring by checking 2 inter-related signals. Almost any sensor can be connected to amplifier, including strain gage sensors, inductive or incremental transmitters, and SSI transducers. Model MP85 uses algorithms for curve evaluation with max of 9 predefined windows for each curve, or 1 master curve with envelope as evaluation criteria. Digital I/Os save statistics on component quality, either on PC or internal MMC card.Original Press Release:

Amplifier Increases Press-Fit Accuracy

The new MP85 measurement amplifier from HBM simplifies two-channel monitoring by checking two inter-related signals. This checks that the optimum combination is used for greater fitting accuracy

Manufacturers dependant on high throughput production lines can benefit from using the MP85. For example, process quality during the press fitting of bearings or sleeves can be improved, by checking the applied force against the displacement curve.

Similar two-channel processes occur when monitoring clinching and fitting during assembly tasks. The MP85 can also be used for monitoring rotational torque or angle curves in component and function testing, or for circularity tests where the rotational angle and displacement must be evaluated.

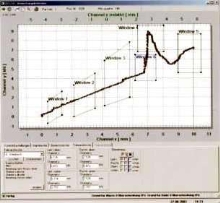

Almost any sensor can be connected to the MP85, such as strain gages, inductive or incremental transmitters, and SSI transducers. The MP85 uses high-performance algorithms for curve evaluation with a maximum of nine predefined windows for each curve, or one master curve with envelope as evaluation criteria. Users have the option of switching between absolute and relative reference co-ordinates to simplify parameter setting.

The MP85 uses digital I/Os to save statistics on component quality, either on a PC or an internal MMC card for later archiving. The MP85 is available in a Profibus version, the MP85DP, ensuring optimum connectivity in the automation environment through CANopen and Profibus interfaces or digital I/Os.

To complement its amplifiers, HBM supplies a complete range of force, pressure and displacement transducers and torque flanges for comprehensive monitoring of production processes.

For more information contact:

Robert Davis, HBM Inc.,19 Bartlett Street, Marlborough, MA, 01752 Email: robert.davis@hbm.com Tel: 800-578-4260 Tel: 508-624-4500 Fax: 508-485-7480 Web: www.hbm.com

About HBM:

HBM, with U.S. headquarters located in Marlborough, Mass., is a leading global supplier of measurement technologies, products and solutions for industrial test and measurement applications. HBM provides complete measurement solutions - from sensor to software - for industrial and laboratory applications. Its wide range of measurement parameters includes force, torque, weight, strain, displacement and pressure. Primary markets include aerospace, automotive and manufacturing.

HBM is a wholly owned subsidiary of Spectris plc.

Issued by: Paul Doughty, Senior Account Manager, Armitage Communications, Mill House, Wandle Road, Beddington, Croydon, Surrey, CR0 4SD Tel: +44 20 8667 2207; Fax: +44 20 8667 9426 Email: paul.doughty@armitage-comms.co.uk