Masking Material protects metal component surfaces.

Press Release Summary:

Available in gel, brush-on, or spray-on formulations, SpeedMask® UV Curable Masking Resin provides surface protection from contamination caused by acids, alkalines, plating solutions, and ambient debris from air plasma spray, HVOF, grinding, peening, and grit blasting. Single-component, temporary masking resin is solvent-free, non-flammable, urethane-based, and water-soluble, and easily peels, dissolves in water, or burns off once the surface treatment process is completed.

Original Press Release:

New Masking Material Replaces Tape and Solvent-Based Lacquer for More Thorough and Economical Surface Treatment Protection of Precision Metal Components

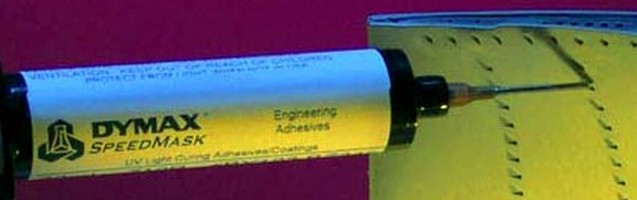

Torrington, CT: SpeedMask® UV Curable Masking Resins, a revolutionary new easy-on, fast-off masking system from Dymax Corporation replaces cumbersome and costly labor-intensive, multi-step processes that utilize adhesive tapes or solvent based lacquers to protect complex high performance turbine components, orthopedic implants, implant hardware, surgical instruments and medical devices during dry or wet chemical surface treatment processing.

Dymax SpeedMask UV temporary masking resins provide thorough and effective surface protection from contamination caused by acids, alkalines, plating solutions and ambient debris from air plasma spray, HVOF, grinding, peening and grit blasting used during surface treatment processing. Once the surface treatment process is completed, the Dymax SpeedMask maskant can easily peel, dissolve in water or burn off.

Traditional tape and lacquer masking operations are highly dependent on the skill, experience and steady hand of the operator. While it has been inexpensive to purchase some tapes and lacquer; the cost for product set-up application and removal, resulting surface defects, scrap, environmental compliance, production delays and material waste can be staggering.

Tape maskants require skill and dexterity to carefully wrap product surfaces. Gaps and overlaps that permit blasting or grinding media, shot, or chemical solution to migrate may produce out of spec parts that either become scrap or require additional re-working-creating a substantial quality issue with costly and time-consuming delay ramifications.

The time-consuming and delicate post-treatment tape removal process often necessitates even greater care than the initial wrapping; since this is where marring of the protected surface most often occurs.

Hidden expenses for high VOC solvent-based lacquer formulations include the time-delay curing process with inherent product storage space requirements, manufacturing bottle-neck, and product application and storage protocols that include the purchase and installation of elaborate exhaust and air handling systems. To compound the process, the removal of lacquer masks often requires the use of an additional solvent.

The solvent-free, non-flammable, urethane-based and water-soluble SpeedMask polymer resins are available for use in manual or automatic applications in a variety of gel, brush-on or spray-on formulations in a wide range of viscosities.

Shelf-stable single component SpeedMask resins do not require measuring and mixing prior to use and are available in syringe and bulk packages measured by volume or weight.

DYMAX product engineers are available to discuss masking applications, recommend products, or to develop custom formulations to meet specific applications.

For more information, please contact Ms. Virginia Read; DYMAX Corporation; 51 Greenwoods Road; Torrington, CT 06790; Tel: (860) 482-1010; vread@dymax.com; www.speedmask.com.