Linear Drive offers out-of-the-box accuracy of ±60 µm.

Press Release Summary:

Featuring anodized aluminum construction with stainless steel hardware and polyurethane/steel reinforced belt, ServoBelt reaches accelerations in excess of 4 g at speeds to 5 m/sec. Single motor supplies peak forces up to 880 N and continuous forces to 300 N. Available with 16,000 and 20,000 CPR rotary encoders, drive features unidirectional repeatability to ±10 µm and bi-directional repeatability of ±40 µm. All bearings are lubed-for-life with no maintenance required.

Original Press Release:

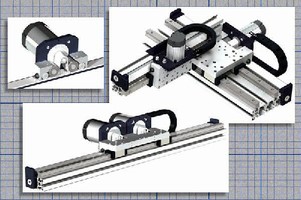

ServoBelt: Belt-Drive Economy with Screw-Drive Performance

Goleta, CA, September 10, 2008-Bell-Evermann, a leading motion device manufacturer, is announcing the availability of the innovative ServoBelt linear drive, which provides belt-drive economy with screw-drive servo responsiveness, accuracy and repeatability,

and linear motor-drive speed.

At the heart of the technology is a static bonded lower belt that meshes with the upper dynamic belt so that the active belting under tension is only a few inches long. Servo tuning can have much higher gains than conventional belts, because stiffness is high and does not change throughout the travel.

Featuring anodized aluminum construction with stainless steel hardware along with high performance polyurethane/steel reinforced belt, ServoBelt reaches accelerations in excess of 4g at speeds to 5 meters/second. Out of the box accuracy is ±60µm with unidirectional repeatability to ±10µm, and bi-directional repeatability is an amazing ±40µm. Single motor supplies peak forces up to 880N and continuous forces to 300N. All bearings are lubed-for-life, no maintenance required, and 16,000 and 20,000 CPR rotary encoders are standard.

Stiffness, accuracy, and repeatability are greatly enhanced by the patented ServoBelt design versus a standard belt-drive. A wide variety of chassis can be configured to virtually any length to suit your needs. Other benefits include:

o Actuators and stages are configurable as multi-axis Cartesian and gantry robots.

o Modules may be purchased as single axis elements for your OEM equipment or as a completely integrated multi-axis robot with amplifiers, cables and optional linear encoders.

o Multiple carriages can be supplied for independent motions on the same axis, and dual motor carriages are available to double our standard linear forces.

o Five motor choices in both NEMA 23 and NEMA 34 frame sizes for easy configuration, or units are available for mounting of third party motors.

o All chassis are based on Bosch T-slot extrusions for ease of integration and a wide array of mounting hardware.

o Unlimited length for large format applications

For a full product description, download the Tech Specs datasheet from http://bell-everman.com/Resources/ServoBelt_Techsheet_web.pdf

About Bell-Everman

At Bell-Everman, we specialize in delivering innovative solutions for both high speed and high accuracy rotary and linear motion devices.

Each product is viewed as a building block that can be customized for the OEM to obtain optimum performance in a given application. From single axis of motion to highly integrated mechanisms, the design and engineering team at Bell-Everman will seriously consider the challenges, and offer an invaluable solution.

Bell-Everman's strength is, ultimately, in finding and developing these solutions. Our award winning designs have given customers both economy and cutting edge market superiority.