Inspection System is engineered for selective soldering systems.

Press Release Summary:

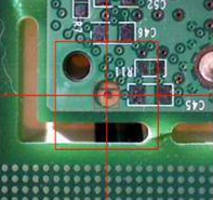

Suited for use with RPS selective soldering systems, RPS Vision Correct(TM) fiducial inspection and auto correction solution uses stored images to validate known fiducial points and other indicators. Soldering process will stop if fiducial patterns are not found, preventing damage to PCBs. System also identifies position errors of fiducials and uses correction algorithms to adjust soldering program by X and Y axis deltas. It offers position correction accuracy to ±0.005 in.

Original Press Release:

RPS Introduces New 3D Fiducial Vision Inspection

RPS Develops Affordable and Easy-To-Use RPS Fiducial Correct(TM) | Fiducial Recognition and Automatic Position Correction for High Precision RPS Selective Soldering Systems

Spokane Valley, WA - RPS Automation LLC, a manufacturer of precision soldering automation equipment to the OEM, circuit board manufacturing and assembly industries, today announced the introduction of RPS Vision Correct(TM), a fully integrated fiducial inspection and auto correction solution for use with all RPS selective soldering systems. This product option is available immediately and will be at APEX 2010 | Las Vegas.

Reid Henry, Engineering Director for RPS, stated, "this is a major leap forward in ease of use, affordability and performance. Engineered specifically for RPS selective soldering, our new fiducial inspection package will enable automated high precision soldering accuracy which is so important to RPS customers."

RPS Fiducial Correct uses stored images to validate known fiducial points and other indicators. The soldering process will stop if fiducial patterns are not found- preventing damage to high value PCB's that may be improperly loaded. Fiducial Correct will also identify position errors of detected fiducials and use correction algorithms to adjust the soldering program by the X and Y axes deltas.

"This new vision correction system is fast, accurate and easy to use. This is another RPS engineering innovation that sets RPS selective soldering apart in performance and ease of use," said Reed Gaither, CEO of RPS Automation.

Key features of RPS Fiducial Correct include:

o High Def Video Camera and White LED Ring Light

o Precision Position Correction ±0.005" | 0.127 mm

o Sensitivity Control for Image Recognition and Search Regions

o Integration with RPS CamConductor(TM) Programming Software

o Availability on the Complete Line of RPS Selective Soldering Systems

ABOUT RPS AUTOMATION LLC

RPS Automation designs and builds a complete line of automated selective soldering, lead tinning and component test and steam aging equipment for electronics and circuit board manufacturing and assembly. RPS has over 20 years of automated soldering experience and more than 480 installations and 285 global customers. All systems are built in the USA. Easy to use software, extensive warranty coverage, and exceptional service are standard with every system.

More information on RPS Automation can be found at www.rpsautomation.com