Injected Metal Assembly System optimizes joining capacity.

Press Release Summary:

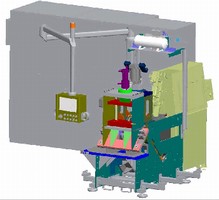

Offering max shot volume up to 500 g, Model AM 51 Injected Metal Assembly System allows for forming and joining of large component assemblies and end terminations. Machine features stationary operating head, 2-stage melt pot, and pneumatic injection. IMA(TM) technology uses molten zinc alloy to die cast component while it is simultaneously joined to other components in assembly, or to form and join end termination directly onto wire, cable, rod, or shaft.

Original Press Release:

FisherTech Increases Assembly/Joining Capacity 10-Fold

The capacity of FisherTech's Injected Metal Assembly (IMA(TM)) process has been increased 10-fold with the launch of the AM 51 system. A maximum shot volume of up to 500 grams allows for forming and joining of much larger component assemblies and end terminations. New design features, such as a stationary operating head, shot control and a two-stage melt pot, provide options for advanced automation up to full robotic operation. Pneumatic injection increases operating capability by 50 per cent for greater productivity, reduced operating costs and improved die cast integrity.

IMA technology uses molten zinc alloy to die cast a component while it is simultaneously joined to other components in an assembly, or to form and join an end termination directly onto a wire, cable, rod or shaft. This manufacturing process eliminates one or more pre-manufactured parts from the assembly as well as multiple joining methods for increased cost saving. The precision die casting tool ensures high quality, close tolerance part-to-part consistency with no secondary finishing required. The zinc alloy, with mechanical properties equivalent to low carbon steel, forms a high strength component, and the alloy's fluidity allows casting of complex, intricate detail.

For more information on the FisherTech's AM 51 system, e-mail info@fishertech.com or call 866-536-2278.

FisherTech is a division of FisherCast Global Corporation, Peterborough, Ontario, Canada and Welshpool, Wales, UK, a global leader in high precision molten metal injection technologies. FisherTech's Injected Metal Assembly systems continue to provide OEM's in the global automotive vehicles, industrial controls, appliances, electronic components, power tools, hardware and telecom market sectors with cost-effective manufacturing solutions for component assembly and joining, and termination of cables and wires.

"Injected Metal Assembly" and "IMA" are trademarks of FisherCast Global Corporation.