Heat Exchangers come with 90° bends.

Press Release Summary:

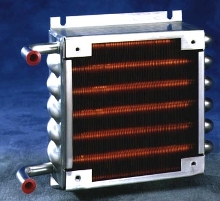

Models 4000 and Aspen stainless steel heat exchangers are suitable for deionized water and other corrosive liquids that react with copper. Both models are available with 90° deg bends on inlet/outlet tubes. Various fittings allow tubing connections to be configured into 24 different orientations. Applications include medical and industrial lasers, medical imaging, analytical instruments, batch ovens, machine tools, and effluent gas scrubber systems.

Original Press Release:

Lytron Introduces 90° Bends on the Inlet/Outlet Tubes as a Standard Option on Stainless Steel Heat Exchangers

July 1, 2002, Woburn, MA - Lytron, the Total Thermal Solutions(TM) company, announces 90° bends on the inlet/outlet tubes are a standard option on the 4000 and Aspen stainless steel heat exchangers. OEMs used 90° fittings to configure tubing connections for specific applications. The minimum order quantity is 25 pieces. Twenty-four different orientations are offered and drawings showing the bend and tube length are located on the website www.Lytron.com.

Charlie Carswell, President of Lytron, said, "By developing standard parts, we have streamlined the design process. Customers can adjust the fitting orientation as needed and feel confident that Lytron can meet their requirements. We have built our reputation as the Total Thermal Solutions(TM) company on engineering and manufacturing flexibility to consistently meet our customers thermal challenges."

Lytron's stainless steel heat exchangers are used with deionized water and other corrosive liquids that react with copper. These heat exchangers find application in many different industries, including medical and industrial lasers, medical imaging, analytical instruments, batch ovens, machine tools, and effluent gas scrubber systems. Lytron's new Aspen line, our latest innovation in stainless steel heat exchangers, combines low price, low pressure drop, and light weight with excellent heat transfer and superior fluid integrity. Lytron's 4000 Series heat exchangers provide maximum heat transfer while preserving absolute fluid integrity.

Lytron is the only Total Thermal Solutions(TM) provider that is ISO 9001 registered. ISO certification assures users that Lytron's liquid-cooling products are defect-free and able to provide years of reliable, leak-free service. For over forty years, Lytron has been well known in the industry for consistent high quality and on-time delivery.

Lytron designs, develops and manufactures high performance heat transfer systems and components. Its products include recirculating chillers, cold plates, compact non-refrigerated cooling systems, aluminum oil coolers, copper tube-fin heat exchangers, stainless steel tube-fin heat exchangers, compact brazed-plate heat exchangers, and economical OEM coils. For more information, call Lytron at 781-933-7300 or visit the web site at www.lytron.com.