Handling System improves flow of cohesive powders.

Press Release Summary:

Powder Handling System consists of Type 3 bulk bag discharger, fitted with Hogan bin discharger and aero-mechanical conveyor. By using pneumatic massage paddles and bag tensioning device, Type 3 improves material flow out of bulk bag with no dramatic degradation. Aero-mechanical conveyor creates moving current of air in which powder flows, and Hogan bin discharger acts as flow promoter by using suspended series of blades controlled by vibrator.

Powder Handling System consists of Type 3 bulk bag discharger, fitted with Hogan bin discharger and aero-mechanical conveyor. By using pneumatic massage paddles and bag tensioning device, Type 3 improves material flow out of bulk bag with no dramatic degradation. Aero-mechanical conveyor creates moving current of air in which powder flows, and Hogan bin discharger acts as flow promoter by using suspended series of blades controlled by vibrator.Original Press Release:

Spiroflow Systems Handles Cohesive Powder

Charlotte, North Carolina---Spiroflow introduces a complete handling system ideal for cohesive powder such as Titanium Dioxide.

Often, these powders will have difficult characteristics when used in conveyors or bulk containers such as Bulk Bags. These characteristics include bridging, ratholing or flushing. Bridging occurs when the powder compacts itself over the outlet and will not flow. Ratholing produces a small inner core of powder that will readily flow, leaving an immovable, larger outer core of powder resistant to discharge. The opposite of these actions is a total "flushing" of powder characterized by an uncontrollable discharging.

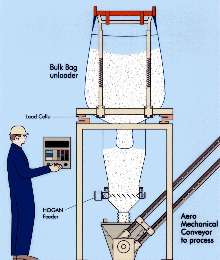

The Spiroflow Type 3 Bulk Bag Discharger, fitted with a Hogan Bin Discharger and Aero-Mechanical Conveyor, dramatically improves powder flow by incorporating flow aid technology. By using pneumatic massage paddles and a bag tensioning device, Spiroflow's Type 3 improves material flow out of the Bulk Bag with no dramatic degradation.

The Hogan Bin Discharger, fitted between the Type 3 Discharger and Aero-Mechanical Conveyor, acts as a flow promoter by using a suspended series of blades controlled by a vibrator to gently vibrate the powder into the Aero-Mechanical Conveyor. The blades are free to rotate to 90 degrees from horizontal. Not only can the blades be vibrated for easier material discharging, but electric actuators can also be attached to the housing.

The Aero-Mechanical, also known as a "rope and disk" conveyor, uses a continuous rope and travels through a tube with a series of equally spaced disks secured to it. The unit creates a moving current of air in which the powder is conveyed, similar to the effect of a vacuum or pneumatic system. However, the Aero Mechanical Conveyor does not need a cyclone or filter to separate the product from the air. This type of conveyor is applicable to horizontal or vertical conveying up to 20-25m.

Spiroflow is a worldwide supplier of a wide range of both standard and custom powder handling equipment, specializing in Bulk Bag Dischargers, Bulk Bag Fillers, Aero-Mechanical, Flexible and Pneumatic Conveyors, and Bag Packing equipment.

For more information about Spiroflow powder handling equipment, telephone 704-291-9595, fax 704-291-9594 or email info@spiroflowsystems.com. Spiroflow can also be found on the Internet at www.spiroflowsystems.com.