Handling System consists of modular components.

Press Release Summary:

HBK Modular System uses matched components that can be used individually or combined. KBK Track is available in steel or aluminum with inside running surface protected from dust and spray. Crab Frames are designed for rigid load handling. Slewing cranes with KSL pivot arms support load capacities of 220 lb and serve 360 deg working area. Pillar jib cranes have load capacities of 1100 lb. Load handling modules engage and hold load to be handled.

Original Press Release:

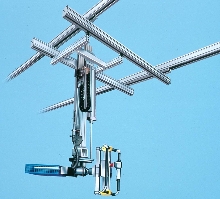

Demag New HBK Modular Handling System

April 2002, Solon, OH - Demag Cranes and Components Corp. announces the introduction of its new HBK Modular Handling System. HBK consists of a variety of perfectly matched components that can be used individually or combined to create

complete load-handling systems. All elements are ergonomically designed to accommodate workplace safety, based on the latest load handling specifications and legislation. "Like an erector set, the HBK modular system allows project and design engineers to quickly select from a wide range pre-engineered components. These modular components fit together easily to create an extremely cost effective and ergonomic load handling system," said John Paxton, Vice President Products.

HBK Modular Handling System component highlights include:

- Demag KBK (Steel) and Demag KBK Alu (Aluminum) Track Systems.

These systems make up the Load Carrier Module of the HBK product group. Demag KBK Track features a cold rolled steel track profile that offers low dead weight, high rigidity and a tough powder coated finish. The new Demag KBK Alu Enclosed Track features an extremely lightweight extruded aluminum profile with high rigidity, and a smooth anodized surface. Both rails offer an inside-running surface that is protected from dust and spray in the surrounding environment.

- HBK Modular System Lifting Components include

Demag D-Arm pneumatic parallelogram arms

D-Lift Vertical Balancers

Demag Air Balancers

DK (electric) Chain Hoists

- KBK and Alu Trolleys are fitted with four plastic travel wheels mounted on anti friction bearings, feature maintenance-free, low wearing, smooth running characteristics.

- HBK Crab Frames are designed for rigid load handling and are used to operate load-lifting modules in Demag KBK or KBK Alu installations.

- Slewing cranes with KSL pivot arms support load capacities of 220 lbs. and serve a 360-degree working area, making it possible to bypass obstacles.

- KBK Pillar and wall-mounted jib cranes are used for simple lifting operations with load capacities of 1100 lbs. Wall-mounted slewing cranes require no floor space; pillar-mounted can be mounted anywhere.

- Load orientation modules, either electrically or pneumatically powered, include slewing units with up to a 180-degree range, or turning units with up to a 350-degree range.

- Load handling modules securely engage and hold the load to be handled.

-Mechanical load handling modules, such as load forks, load hooks, pantograph-type tongs or PGS mechanical grippers are frequently combined with flexible Demag Load-Lifting modules.

- Pneumatic load handling modules - gripping tongs, parallel grippers or expanding mandrels - all have the same connection footprint

- Control systems include up/down, single-load balance, dual-load balance, or control with the new D-Grip, which detects and translates small hand forces into movement. Each are designed to match the equipment and the task to be performed.

Demag Cranes and Components solves material handling and ergonomic challenges through the utilization of innovative cranes and components. These include chain and wire rope hoists, gearmotors, wheel block systems, cable balancers, lift assists, enclosed track systems as well as friction wheel drives. For more information on Demag North American sales, service and distributor locations, contact Demag Cranes and Components at demaq-us.com or call us toll free at 1-800-321-6560.