Gas Turbine Upgrade Technology enhances output, fuel efficiency.

Press Release Summary:

Available for 9F-3 and 9E gas turbines Advanced Gas Path (AGP) technology enables respective output increases of up to 6% and 3.8%, fuel efficiency increases up to 2% and .9%. Maintenance intervals can reach up to 32,000 hr for 9F-3 and as long as 32,000 hr/1,200 starts for 9E, extending outage intervals up to 33% for both. Along with OpFlex™ advanced controls software, AGP technology provides hardware design and materials improvements to components of GE gas turbine hot gas path system.

Original Press Release:

GE's High-Performing Advanced Gas Path Solution Expanded to 9F-3, 9E Gas Turbine Fleets and Will Deliver More Power to Growing Asia Region and Beyond

GE’s 9F-3 and 9E Advanced Gas Path Solutions Deliver Industry-Leading Upgrade Performance

Upgrade Technology Marks First of Its Kind Available in Both Gas Turbine Class Sizes

ENKA is the First GE Customer to Invest in 9F-3 AGP Technology, Upgrading 10 Gas Turbines in Turkey

Proven Solution Expanded from GE’s Global 7F-3 AGP Customer Portfolio Which Includes Sites in South Korea, Taiwan

BANGKOK—GE (NYSE: GE) announced today the expansion of its high-performance Advanced Gas Path (AGP) portfolio to its 9F-3 and 9E gas turbine customers operating in Asian energy markets and around the globe. This technology, which is proven to deliver industry-leading upgrade performance, marks the first of its kind available for comparably sized gas turbine assets in both classes. GE made the announcement today at the 2013 POWER-GEN Asia Conference & Exhibition.

“GE’s AGP technology exemplifies the levels of flexibility and performance our customers demand to remain competitive in both growing and mature energy markets around the world,” said Fintan Tuffy, general manager of Fleet Analytics & Performance Management for GE’s Power Generation Services business. “With a number of Asian markets ranking at the top of expected energy demand growth regions over the next decade, this solution can play an integral role in helping our customers meet these future needs by unlocking the full potential of their existing assets.”

With more than 120 AGP systems sold and 37 upgrades already in operation on GE 7F-3 gas turbines around the globe, this proven solution can now unleash higher performance for GE customers with installed assets such as:

9F-3

Output increase up to 6 percent**

Fuel efficiency increase up to 2 percent**

Maintenance intervals as long as 32,000 hours (extending outage intervals up to 33 percent)**

9E

Output increase up to 3.8 percent**

Fuel efficiency increase up to .9 percent**

Maintenance intervals as long as 32,000 hours/1,200 starts (extending outage intervals up to 33 percent)**

ENKA, which generates more than 13 percent of electricity for Turkey, has placed the first order for GE’s 9F-3 AGP technology for 10 of its gas turbines at the Gebze, Adapazar and Ãzmir power plants. The upgrades are expected to deliver a total of up to approximately 150 additional megawatts (MW) of power, enough to generate electricity for more than 200,000 additional households in Turkey. ENKA also expects to lower its emissions footprint with the installation of the AGP solution in tandem with GE’s Dry Low NOx (DLN) 2.6+ combustion system upgrade. Installation of the technologies is scheduled to begin in late 2015, with a targeted completion date of 2018 for all 10 gas turbine upgrades.

“The performance improvements this solution delivers to our plants will allow us to maximize the value of the energy we provide through power purchase agreements,” said ENKA O&M Chairman Mr. Tahsin Kösem. “This collaborative effort with GE will also put our sites in a better position with more available power and flexibility for electricity markets with demand increases being forecasted across Turkey. Additionally, this project increases ENKA’s contribution to help meet the Turkey 2023 Vision, which contains goals of increasing efficiency and lowering the country’s carbon footprint.”

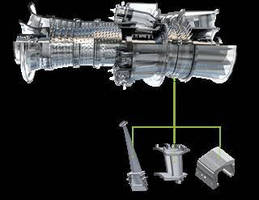

AGP technology advancements feature hardware design and materials improvements to the components of GE’s gas turbine hot gas path system. These innovations are coupled with GE’s OpFlex* advanced controls software to expand gas turbine performance and enable GE customers to operate their power plants more dynamically. The AGP’s hardware and software technologies were developed based on data insights gained through analysis of GE’s more than 100 million hours of operating data on its global gas turbine fleet of more than 1,600 monitored units.

Asian power generation entities are expected to experience the world’s highest regional demand growth for power over the next several decades. Across Asia, average energy demand growth is estimated at 3.7 percent annually through 2030 , with Southeast Asian demand potentially expanding nearly 90 percent over the same period of time. GE’s AGP technology enables customers with existing gas turbines in rapidly growing economies in Asia and beyond to expand their power capacities without investing in new infrastructure or to complement new power plant construction.

GE customers around the globe currently are operating or will soon install AGP technology on their 7F-3 gas turbines to address a wide scope of regional market dynamics:

Korea Southern Power Company, Ltd. installed two AGP systems at its Pusan plant in 2012 to generate 25 MW of additional power needed for growing electricity demand and to expand the region’s low reserve margin of power.

In Taiwan (R.O.C.), the Chia Hui Power Station will install AGP technology on three gas turbines in early 2014 to improve the plant’s heat rate, position the plant more competitively amid higher fuel prices and to manage its assets more efficiently long term.

TransCanada Energy Ltd.’s Ravenswood power plant in New York, U.S., expanded its output by 7 percent with the AGP solution, enough to power 10,000 additional households in New York City by upgrading just one gas turbine. TransCanada’s MacKay River cogeneration facility in Alberta, Ca., has improved its operational availability using AGP technology to support its customer’s nearly 24-hour-a-day manufacturing cycle. The site also has maintained its low emissions footprint to remain aligned with Alberta’s clean energy policies.

Calpine Corporation’s Los Medanos and Pastoria plants in California, U.S., and Westbrook facility in Maine, U.S., have experienced a 5.5 percent output increase since installing AGP technology on six GE gas turbines. They also have experienced an approximately 1 percent improvement in site heat rates. This performance has better positioned the plants to bid more competitively for power demand, as well as capitalize on opportunities to capture additional revenue.

IBERDROLA, Mexico’s leading private power generation company, installed AGP upgrades on eight units at its TAMAZUNCHALE and Altamira V plants to better manage operational costs including fuel consumption. Additionally, the output gained from the upgrades has enabled IBERDROLA to increase its operational revenue by winning more bids for power in the region.

GE’s 9F-3 and 9E gas turbine AGP technology were adapted from GE’s 7F-3 AGP solution, which has been qualified for GE’s ecomagination portfolio. This technology enables GE customers to reduce fuel consumption as well as CO2 emissions, while operating with the flexibility they need amid shifting market conditions. Ecomagination is GE’s commitment to imagine and build innovative solutions to today’s environmental challenges while driving economic growth.

The AGP solution is offered through GE’s FlexEfficiency* Advantage for F-Class gas turbine and LifeMax* Advantage for B/E-Class gas turbine platforms. These portfolios deliver hardware- and software-blended solutions that enable GE customers to unleash the full performance and value of their existing assets. Only GE customers are empowered to harness these upgrades, in tandem with data-driven insights from the world’s largest gas turbine fleet, to gain the advantages they need for success, as they define it.

The FlexEfficiency Advantage and LifeMax Advantage portfolios support GE’s Predictivity™ solutions platform. Predictivity solutions tap into GE’s networked fleet of gas turbines, along with data analytics capabilities and our people at work to help customers make better business decisions and lower their operational risk.

About GE

GE (NYSE: GE) works on things that matter. The best people and the best technologies taking on the toughest challenges. Finding solutions in energy, health and home, transportation and finance. Building, powering, moving and curing the world. Not just imagining. Doing. GE works. For more information, visit the company's website at www.ge.com.

About GE Power & Water

GE Power & Water provides customers with a broad array of power generation, energy delivery and water process technologies to solve their challenges locally. Power & Water works in all areas of the energy industry including renewable resources such as wind and solar; biogas and alternative fuels; and coal, oil, natural gas and nuclear energy. The business also develops advanced technologies to help solve the world’s most complex challenges related to water availability and quality. Power & Water’s six business units include Distributed Power, Nuclear Energy, Power Generation Products, Power Generation Services, Renewable Energy and Water & Process Technologies. Headquartered in Schenectady, N.Y., Power & Water is GE’s largest industrial business.

Follow GE Power & Water on Twitter @GE_PowerWater.

*Trademark of General Electric Company; may be registered in one or more countries.

**Performance varies depending on gas turbine frame type and configuration.

Media contacts:

Masto Public Relations

Email: information@mastopr.com

Shaun Wiggins

GE Power & Water

Phone: +1 518 385 5992

Email: shaun.wiggins@ge.com

Gina DeRossi

Masto Public Relations

Phone: +1 518 786 6488

Email: Gina.derossi@mastopr.com