Gas Blending System blends up to 5 component gases. .

Share:

Press Release Summary:

To create custom gas mixtures, Gas Blending System draws from 5 separate pure gas sources, generating controlled blend across broad concentration range for calibration or validation standards. Automatic or manual dynamic mixing allows creation of multiple gas concentrations in real-time, minimizing inventory of multi-component custom gas cylinders. Dilution ratios ranging from 1:1 to 10,000:1 allow calibration of most analyzer ranges from one cylinder of each gas type.

Original Press Release:

New Parker Gas Blending System Reduces Cost in Analytical Applications

System allows users to blend gases to produce custom gas mixtures

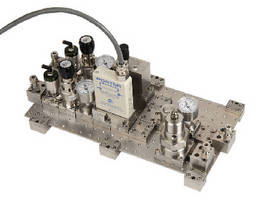

HUNTSVILLE, Ala., - The Instrumentation Products Division of Parker Hannifin Corporation, the global leader in motion and control technologies, introduces the Parker Gas Blending System. The system allows users to blend or dilute up to five component gases to produce customized gas mixtures for precise calibration or validation standards. Created in response to industry demand for a way to reduce the cost of blending/diluting gas for laboratory, industrial, and process analytical applications, this system can produce significant savings of up to 20 percent over the purchase of custom pre-blended gas.

"Typically, a custom blended gas is used in applications analyzing process streams in the chemical, petrochemical, and industrial markets," said Mike Cost, Applications and Innovation Engineer for the Instrumentation Products Division (IPD). "Purchasing custom blended gas, while routine, can be very expensive, and because the gases are already blended, the component concentrations can't effectively be changed. Parker's Gas Blending System offers control and flexibility in the blending and dilution of gases, as well as complete traceability, customization, and reduced cost."

To create custom gaseous mixtures, the Gas Blending System draws from five separate pure gas sources to generate a controlled blend across a broad concentration range. Automatic or manual dynamic mixing allows the creation of multiple gas concentrations in real time, minimizing inventory of multi-component custom gas cylinders. The flexibility of on-site blending allows users to save up to 20 percent over the cost of utilizing custom blended gas and reduce tubing installation requirements. Actual costs and potential savings will vary with location, gases used, and gas supplier.

The Gas Blending System can be used for gas dilution, varying the concentration of both pure and pre-blended gases. A broad range of dilution ratios (1:1 - 10,000:1 standard) allows calibration of most analyzer ranges from one cylinder of each gas type, minimizing gas costs, transport costs, and handling labor. From higher percent to parts per billion (ppb) levels, the system can achieve a variable range of concentrations for automatic calibration of gas chromatographs, FTIRs, process gas analyzers, mass spectrometers, and other gas analytical devices.

The Gas Blending System is built on the Parker IntraFlow(TM) platform. IntraFlow is an ISA/ANSI SP76.00.02-compliant modular sample conditioning system that minimizes space requirements and lowers maintenance costs by allowing standardization of parts. Additional gas circuits can be added later, reducing investment and guarding against obsolescence. Sensors and micro-analytical measurement sensors can also be added to enable remote monitoring through Parker Pilot Pro(TM), a communications interface designed to link plant process control operations and analyzer maintenance networks to facilitate critical process control decision making.

The mass flow controllers in the Gas Blending System are factory calibrated for user-defined gases (i.e., N2, He, Ar, etc.) and give users the ability to remotely control the system. The system can also be paired with Parker IPD Volumetric Flow Controllers for the manual blending of gases.

For more information regarding Parker's Gas Blending System, visit www.parker.com/ipdus or contact Parker IPD at 256-881-2040.

The Instrumentation Products Division is dedicated to being the global leader in the design, manufacture and distribution of high quality, critical flow and ultra-high purity components for the petrochemical, chemical processing, oil and gas, power generation, water analysis, biopharmaceutical, semiconductor, and analytical equipment industries.

With annual sales exceeding $12 billion in fiscal year 2011, Parker Hannifin is the world's leading diversified manufacturer of motion and control technologies and systems, providing precision-engineered solutions for a wide variety of mobile, industrial and aerospace markets. The company employs approximately 58,000 people in 47 countries around the world. Parker has increased its annual dividends paid to shareholders for 55 consecutive years, among the top five longest-running dividend-increase records in the S&P 500 index. For more information, visit the company's web site at www.parker.com, or its investor information web site at www.phstock.com.