Friction Springs provide shock absorption.

Press Release Summary:

RING-Springs® absorb and dampen high kinetic energy of moving mass in relatively small space, protecting structural components. Design allows them to absorb up to 67% of input energy and return it as heat. Made of spring steel, RING-Springs range from .5-30 in. dia with end forces up to 1 million lb and operating temperatures from -40 to 180°F. They offer uniform stress distribution where stresses are consistent over entire cross-section.

Original Press Release:

Ringfeder's RING-springs® Provide Shock Absorbing Solutions

Westwood, NJ- Ringfeder Corporation® offers high-quality RING-spring® shock absorbing friction springs to protect structural components in a variety of industrial applications. Friction springs are used to absorb and dampen high kinetic energy of a moving mass in a relatively small space.

Applications include: pneumatic hammers, recoil systems in automatic weapons, buffers in railroad car couplers, steel mill/rolling mill end stops, buffers for ferry boats, shock absorbers for heavy industrial doors, buffers for crane end stops and much more. A wide range of sizes and force characteristics are available.

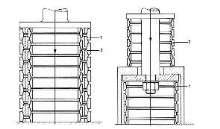

The reliable RING-spring® was founded on the principle of converting impact energy into frictional heat. The design of the RING-spring® allows it to absorb up to 67% of the input energy and return it as heat. The RING-spring® consists of a series of concentric inner and outer rings with mating tapered surfaces that are greased with a special lubricant. When the load is applied, the wedge action of the tapered faces expands the outer rings and contracts the inner rings, allowing for deflection.

Depending on the design, RING-springs® will dampen and absorb the high kinetic energy of a moving mass in compression or tension.

Unlike conventional springs, RING-springs® offer a uniform stress distribution where stresses are consistent over the entire cross-section.

The uniform stress distribution of the RING-spring® permits the fullest use of the material and occupies a minimum amount of space, allowing the relatively small ring stack to absorb a large amount of energy.

RING-springs® are manufactured of high quality spring steel and must pass Ringfeder's rigorous QCQA testing. They require little maintenance, can be employed in temperatures from -400F and 1800F and function within spec for many years. RING-springs® are available with standard spring configurations from .5" to 30" diameter with end forces up to 1 million pounds.

"Ringfeder" translated from German to English literally means "ring spring". They have used this tapered ring principle to develop other Ringfeder products including Locking Elements, Locking Assemblies and Shrink Discs® for shaft/hub connections. Ringfeder offers a wide range of power transmission solutions including: keyless shaft/hub connections, torque limiters, shock absorbing devices, flexible elastomeric couplings, flexible disc couplings and specialty products for all your power transmission needs. For more information on Ringfeder's RING-springs® or the entire line of Ringfeder products, log on to www.ringfeder.com or call 1-800-245-2580.

For more information on this release or additional photography, please call advantage marketing communications at 908-850-8710.