Flexible Destacker feeds aluminum and steel blanks.

Press Release Summary:

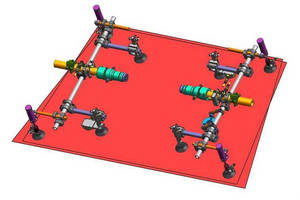

Featuring 2.5 in. dia aluminum round-body tooling, flexible destacking solution successfully separates and feeds both steel and aluminum blanks in various sizes and configurations. During cycle, automation lowers so that peeler suction cups are all level, with front cups spring-loaded and programmed to fire slightly prior to other cups. Air knives then fire to help peel back top sheet, breaking vacuum, which assists in separating blanks.

Original Press Release:

Bilsing Automation's New Destacker Tooling Design Feeds Aluminum and Steel Blanks

Clinton Township, MI -- Bilsing Automation has recently applied its pressroom tooling expertise to the development of a flexible destacking solution that can successfully separate and feed both steel and aluminum blanks in various sizes and configurations. The solution was designed and engineered by Bilsing for flexibility where the end effector can handle multiple parts. It is comprised of the company’s 2.5” diameter aluminum round-body tooling and other Bilsing components.

Whereas traditional steel blank destacking systems rely on magnetic holders for separating the blanks before lifting and transfer, aluminum has no magnetic qualities. Typical aluminum destacker systems employ peel cylinders to lift the corners of the blank with air knives that shoot air in that space to break the vacuum. Another issue is that lubrication on the blanks acts like a glue-agent, causing the blanks to stick together.

To overcome these issues, Bilsing compiled field data for strategic placement of the peel cylinders in its design. During a cycle, the automation lowers so that the peeler suction cups are all level, with the front cups being spring-loaded and programmed to fire just slightly prior to the other cups. The air knives then fire to help peel back the top sheet -- breaking the vacuum, which assists in separating the blanks.

Bilsing originally developed this solution for a customer that wanted to bring components of varying materials running on three different lines to a single pressline. Whereas other suppliers had struggled to solve the issue, Bilsing’s has successfully developed a flexible solution that can handle different materials and sheet sizes.

Bilsing Automation North America is a subsidiary of Bilsing Automation GmbH (Attendorn, Germany), a global leader in the development and manufacturing of modular tooling systems for the pressroom, body shop and plastic molding applications in the automotive, food, packaging and glass industries. The company is focused on providing optimum product performance that results in cost reductions, supporting the customer through planning, design, engineering, assembly and commissioning. Bilsing Automation also offers 3D digital simulation and on-site training as part of its service offerings.

Contact Information:

Bilsing Automation – North America

22287 Starks Drive

Clinton Township, MI 48036

586-463-0686

Info.na@bilsing-automation.com

www.bilsing-automation.com

Nancy Lesinski (Agency)

nlesinski@industry-scope.com

248-709-3040

831-308-3040 Fax

www.industry-scope.com