Engineering Plastic suits thermal/electrical applications.

Share:

Press Release Summary:

Designed for applications requiring high dimensional stability, Pyropel® HDT polyamide-imide (PAI) exhibits electrical and mechanical performance at continuous use temperatures from -60 to +260ºC. Fully reacted thermoset does not require post-curing and will not soften or creep. Product is available in pure form in 12 x 12 in. plates with thicknesses of 1/4, 3/8, 1/2, 3/4, and 1 in. as well as in machined parts.

Original Press Release:

New Engineering Plastic for Applications Requiring High Heat Resistance and Dimensional Stability

MANSFIELD, MA - Pyropel® HDT polyamide-imide (PAI) is an engineering plastic designed for thermal/electrical applications requiring high dimensional stability. The material exhibits superior electrical and mechanical performance at continuous use temperatures from -60º to 260ºC.

Pyropel HDT is a fully reacted thermoset offering enhanced properties without the need for post-curing. Fully reacted PAI materials exhibit greater dimensional stability and improved chemical resistance throughout their usable temperature range. Pyropel HDT will not soften or creep like a thermoplastic and has a heat deflection temperature significantly higher than thermoplastics including Ultem®, PEEK(TM), and Torlon®.

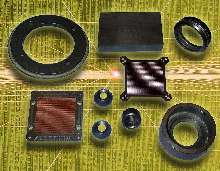

Pyropel HDT is available in pure form (no fillers) in 12"x 12" plates with thicknesses of 1/4", 3/8", 1/2", 3/4", and 1" as well as machined parts. Typical applications include: thermal or electrical isolators, bushings, standoffs, plasma cutting/welding insulator parts, and IC test sockets and contactors for semiconductor chip testing.

For more information, contact: Alan Godbout, Market Development Manager, Albany International/ High Performance Materials, 777 West Street, P.O. Box 9114, Mansfield, MA 02048-9114,

TEL: (508) 337-3008 (x 9590), FAX: (508) 337-8550, e-mail: hpm@albint.com.