Electrode Design/Testing Software extends EDM equipment support.

Share:

Press Release Summary:

Delcam Electrode provides integrated solution for design, machining, and inspection of electrodes. Solution also benefits from options in PowerSHAPE design software, which provides CAD element of overall solution, with option to merge fragmented faces into single, continuous surface. As EDM equivalent of CAM programs for machine tools, scripts provide automated process for programming of diverse machines. Also, data can be output to CERTA shop-floor management software.

Original Press Release:

Delcam Enhances Electrode Solution and Extends EDM Equipment Supported

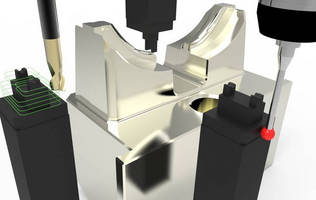

Delcam has added a range of enhancements to its Delcam Electrode integrated solution for the design, machining and inspection of electrodes, and has extended the range of EDM equipment supported by the software. For full details, please visit www.delcam-electrode.com

The system has also benefitted from a number of new options introduced into Delcam’s PowerSHAPE design software which provides the CAD element of the overall solution, in particular, the new option to merge fragmented faces into a single, continuous surface and so produce cleaner, simple electrode geometry. This simplification makes subsequent operations, such as adding draft to complex regions of the model, much easier and also improves the operation of many of the direct modelling tools in the software.

Delcam Electrode can now provide scripts for Exeron and JDMA EPX equipment as well as the previously supported AgieCharmilles (Agievision and CT Millennium controls), Makino EDM, Mitsubishi Electric, ONA EDM, OPS-Ingersoll, Sodick and Zimmer & Kreim.

Scripts are the EDM equivalent of CAM programs for machine tools. They provide an automated process for the programming of the machine, instead of users having to program manually from a set-up sheet. The automated process is much easier and quicker, especially when a number of electrodes are being used on the same component. Furthermore, the direct link removes the human error that could always be possible with manual programming.

In addition, data from Delcam Electrode can now be output to the CERTA shop-floor management software.

Delcam Electrode combines PowerSHAPE, the PowerMILL CAM system and the PowerINSPECT inspection software to give a completely integrated solution for the design, machining and inspection of electrodes. At the heart of the Delcam solution is a novel file format – the .Trode file. This contains all the information for each electrode project, including not only the electrode design but also the machining and inspection information, plus the set-up sheets for its manufacture and use. Having all the required information in a single file simplifies data management as well as increasing overall efficiency.

In the 2014 version, the .Trode file is compatible with Windows Explorer. This new option allows electrode geometry, set-up sheets and script files to be viewed directly from the .Trode file using Windows Explorer with a single click on the desired item.

Data management has also been simplified with the option to output an electrode schedule from the software. The data can be output in HTML, Excel or CSV format as a table describing each electrode required and its key data, such as blank size, undersize value, material etc. This option will, of course, be of most value when large numbers of electrodes are required in a project, for example, for a complex mould tool.

Another enhancement automatically updates the script files based on information gathered during the inspection with PowerINSPECT. The new script file can then provide accurate process information to the EDM machine, avoiding the need for manual updates.

For further information on Delcam Electrode, please contact: -

Peter Dickin

Marketing Manager

Direct phone: 0121 683 1081Â

e-mail: marketing@delcam.com

Delcam plc

Small Heath Business Park,

Birmingham, B10 0HJ, UK

www.delcam.com