Drying System removes water from extruded/coated products.

Share:

Press Release Summary:

Using blowers to deliver 176°F contaminant-free air at constant volume and pressure, DRI-Line Powerpack can dry extruded products from 5-25 mm diameter at speeds in excess of 300 m/min. Drying effectiveness is achieved by passing extruded product through pair of hinged drying heads that deliver high velocity airflow directly to product. Blowers used in Powerpack are housed in stainless steel acoustic chamber to keep noise levels below 85dB(A).

Original Press Release:

Impressive Payback for Extruded and Coated Product Drying System

A new energy-efficient drying unit for water-cooled extruded and coated products has been introduced by air movement specialist, Air Control Industries (ACI) of Chard, Somerset.

Called the 'DRI-Line Powerpack', ACI's innovative system achieves vastly superior drying efficiencies to both compressed air alternatives and other blower-driven solutions available to the industry today.

Removing water from extruded/coated products during manufacture following extrusion or coating application is difficult to achieve due to the way water adheres to products. ACI's unique drying design delivers air at high velocity very close to the surface of the product breaking the surface tension of the retained water and allowing it to be removed effectively.

Impressive payback periods have been demonstrated by extensive customer field trials. When compared to compressed air systems up to 10 fold energy savings have been achieved which potentially equates to savings of £1000s per annum. In fact, so confident is ACI of the system's performance and the achievable savings, the company is offering free on-site trials to potential customers in the UK.

Utilising high efficiency blowers, ACI's DRI-Line Powerpack delivers warm (80o C/176oF) clean, contaminant free air at constant volume and pressures to ensure the drying process is consistent and reliable. It also has the advantage of being 'plug and play' as it runs off a 230V, single phase supply. A version with a 110V supply will also be available shortly.

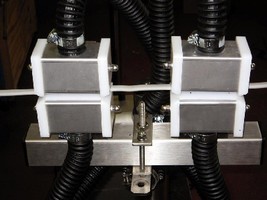

The unit has the ability to successfully dry extruded products from 5 to 25 mm diameter at speeds in excess of 300 m/min. Its drying effectiveness is achieved by passing extruded product through a pair of hinged drying heads that deliver the high velocity airflow directly to the product. The hinged heads are sprung allowing any defect/knot to pass through without any requirement for adjustment.

The blowers used in the Powerpack are housed in a sturdy, stainless steel acoustic chamber that keeps noise levels well below 85dB(A). The drying heads are predominantly fabricated from stainless steel, but also utilise polyethylene for the main facing plates and plenum chamber end-caps for its hard wearing properties.

ENDS

Issued on behalf of:

Air Control Industries Ltd

Silver Street, Chard, Somerset, UK, TA20 2AE Tel. 0845 5000 501 Fax. 0845 5000 502

Contact. Matthew Forknall - matthewforknall@aircontrolindustries.com

Web: www.aircontrolindustries.com