Die-Attach Adhesives offer optimized rheology.

Press Release Summary:

Intended for microelectronics and semiconductor industries, Electraset™ electrically conductive die attach adhesives conform to Test Method 5011 in MIL-STD-883. Electraset™ 620 couples low cure shrinkage with low coefficient of thermal expansion, minimizing chip or device warping and preventing cracking or delamination. Electraset™ 620-2 has virtually no bleed and minimal spreading, tailing, or stringing. Electraset™ 620-3 is used for dispensing, stenciling, and doctor blade application.

Original Press Release:

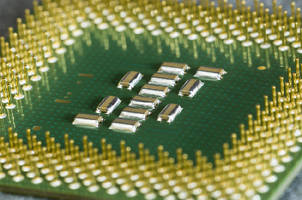

Electrically Conductive Die-attach Adhesives and Adhesive Films

Creative Materials Inc,has introduced Electraset™, a new series of electrically conductive die-attach adhesives for the microelectronics and semiconductor industries. These highly engineered adhesives and adhesive films are designed to meet the highest reliability and highest efficiency standards and will surpass the most demanding industry requirements.

The many advantages of this series of products include optimized rheology, stress management, and maximized conductance. Our adherence to tightly controlled rheology specifications results in lower bleed, less spreading and fewer tailing characteristics when dispensing with advanced pneumatic, auger, and jetting methods. The matching of modulus with thermal expansion properties offers extreme durability and reliability over a wide range of operating conditions. Peak performance is achieved in current carrying capacity and heat dissipation, extending the lifespan of the devices they bond. These adhesives are produced to conform to Test Method 5011 in MIL-STD-883.

Our manufacturing and support of these exceptional products has given customers the benefit of trusting a known manufacturer while utilizing the latest high performance technology. The Electraset™ family of adhesives enables use of various processing conditions while taking into careful consideration diverse engineering requirements. Furthermore, the products’ low ionic levels and low moisture absorption properties provide longer lifespan for devices that are not hermetically sealed. The low outgassing property during high temperature operation or processing also allows for maximizing lifespans in hermetically sealed devices.

Electraset™ 620 couples low cure shrinkage with low coefficient of thermal expansion. These properties serve to minimize and eliminate chip or device warping and prevent cracking or delamination while at the same time maintaining high bond strengths. With a high degree of thermal stability, Electraset™ 620 is designed to prevent gas evolution during high temperature exposure, including solder reflow conditions.

Electraset™ 620-2 has virtually no bleed and minimal spreading, tailing, or stringing. It is recommended for use in applications requiring high mechanical properties coupled with thermal shock resistance. Electraset™ 620-2 provides ease of implementation across a diverse range of platforms and technologies.

Electraset™ 620-3 is used for dispensing, stenciling, and doctor blade application. This product is recommended for applications requiring the highest thermal management requirements with incredible thermal conductivity for composite materials. For filling, potting, or building conductive features or when organic content needs to be minimized, Electraset™ 620-3 provides a unique solution.

Creative Materials, Inc., is a leading manufacturer of custom-formulated electrically conductive inks, coatings, and adhesives.

Creative Materials is ISO 9001 certified, with an extensive product line. Our company has wide-ranging experience in the adhesive, ink and coating industry, combining technical expertise with nimble production capabilities, enabling us to reduce time-to-market for new product applications.