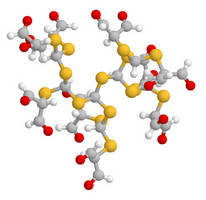

Dendrictic Oligomers exhibit chemical, temperature resistance.

Press Release Summary:

Offering optimized mechanical and physical properties in hard protective coatings, Bomar™ dendritic oligomers exhibit acid and chemical resistance and suit high-temperature, low-viscosity ink applications. Products cure tack free at rate that accelerates processing without defects from early handling. Designed for low shrinkage, oligomers ensure complete, uniform coverage of substrates and adhere to ABS, acrylic, aluminum, glass, polycarbonate, PMMA, polyester, and stainless steel.

Original Press Release:

High-Functionality Oligomers Exhibit Superior Chemical and Temperature Resistance

Dymax Oligomers & Coatings has introduced a family of Bomar™ dendritic oligomers that offers exceptional mechanical and physical properties in hard protective coatings. The materials, ideal for use in high-temperature, low-viscosity ink applications, exhibit superior acid and chemical resistance, making them suitable for applications where harsh chemical spillage occurs, such as chemical processing plants, dye houses, and chemical storage areas.

Bomar dendritic oligomers cure fast and tack free for faster processing and no defects from early handling. Designed for low shrinkage, they ensure complete, uniform coverage of substrates, while demonstrating excellent adhesion properties to ABS, acrylic, aluminum, glass, polycarbonate, PMMA, polyester, and stainless steel.

For additional information, visit www.dymax-oc.com or contact Dymax O&C Application Engineering at O&Ctechnical@dymax.com or 860-626-7006. Dymax Corporation develops innovative oligomer, adhesive, coating, dispensing, and light-curing systems for applications in a wide range of markets. Major markets include aerospace, appliance, automotive, electronics, industrial, medical device, metal finishing, and UV-curable inks & coatings.