Data and Database Management Software

Data Quality Software validates and secures CAD information.

Press Release Summary:

Created for Siemens NX users, NXdoctor validates and repairs 3D CAD data and can be customized to create single standard across manufacturing supply chain. Product Data Quality (PDQ) validation/repair tool lets users validate and secure quality of all sent and received CAD data pertaining to product design and development. In addition to PDQ Validation of 27 critical check items and thresholds, functionality supports automatic healing of entire model or sections and ENF I/O.

Original Press Release:

Elysium to Release New NXdoctor Product Data Quality Tool

Validation and repair plug-in is for all NX CAD. A customized configuration at Nissan integrates suppliers to corporate-wide data standard.

SOUTHFIELD, MI-Elysium Inc., a leading global provider of design data exchange software, today announced the upcoming (April 9) release of NXdoctor, a sophisticated Product Data Quality (PDQ) validation/repair tool specifically created for Siemens NX users.

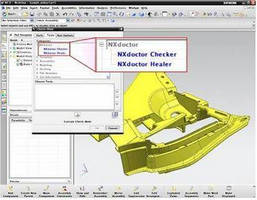

NXdoctor, a Siemens NX plug-in, validates and repairs 3D CAD data and can be customized by OEMs to create a single standard across their manufacturing supply chain. Nissan Motor Company, for example, has adopted customized PDQ guidelines in NXdoctor to assure correct data for any subsequent 3D use scenario.

"Data accuracy reverberates all the way down the supply chain, profoundly affecting every stage of Product Lifecycle Management (PLM)," says Sakae Morita, General Manager of Elysium Co. Ltd., the parent of U.S.-based Elysium Inc. "Adopting NXdoctor in the early design phase will help NX users at any level improve efficiency throughout the manufacturing enterprise."

At Nissan, the global CAD standard is Siemens NX. The automobile manufacturer's PDQ criteria dictate a unique 3D data control checklist for itself and for suppliers. NXdoctor enables both Nissan and those who work with the company to validate and secure the quality of all sent and received CAD data pertaining to product design and development. The software allows users to check 3D data directly from within Siemens NX in accordance with Nissan's strict specifications. Data meeting these requirements is validated by an encrypted authentication key.

"Many companies are starting to implement PDQ management to prevent issues caused by problematic CAD data," says Elysium Inc. COO/Vice President Ken Tashiro. "There is a particular need for automatic error detection, modification and validation of received data because it's very time-consuming and costly for designers to detect and correct those PDQ errors within their own CAD. NXdoctor resolves these issues."

Major features of the new general release of NXdoctor include:

For further information about NXdoctor capabilities, go to www.elysiuminc.com

NOTE: Siemens and the Siemens logo are registered trademarks of Siemens AG. NX and Teamcenter are trademarks or registered trademarks of Siemens Product Lifecycle Management Software Inc. or its subsidiaries in the United States and in other countries. All other trademarks, registered trademarks or service marks belong to their respective holders.

As shown in this analysis of a plastic injection-molded automotive component, NXdoctor is an integral part of Nissan's 'Check-Mate' data validation process.