Cutting Machines offer inkjet marker option.

Press Release Summary:

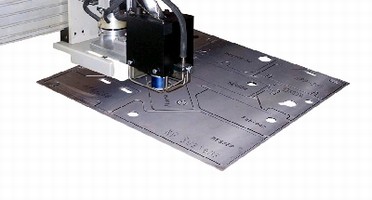

Available as option for plasma and oxyfuel cutting machines, Ink Jet Marker provides alphanumeric labeling with printing in one direction of travel, in addition to line and contour marking for showing bend lines and feature locations. It uses 7 dot head to provide legible characters up to 1 in. tall at speeds up to 17 characters/sec. With operating range of -5 to +45°C and humidity range of 10-90% RH, marker is suited for fabricating environments.

Original Press Release:

MG Systems Introduces Ink Jet Marker at Fabtech

MG Systems and Welding will introduce a new optional Ink Jet Marker at Fabtech 2006. The basic Ink Jet Marker provides fast and quiet alphanumeric labeling with printing in one direction of travel, in addition to line and contour marking for showing bend lines and feature locations. The enhanced version adds a rotation axis to allow text and lines to be oriented at any angle on the surface being marked.

The Ink Jet Marker uses a 7 dot head to provide highly legible characters up to 25mm (1 inch) tall at speeds up to 17 characters per second. This marker is especially designed to work in the hot, dusty and humid environments encountered in fabricating applications, with an operating temperature range of -5°C to + 45°C and a humidity range of 10% to 90% RH. Black MEK-based ink is used.

The print head receives a text string from the part program and executes the printing commands in a single motion.

The Ink Jet Marker is offered as an option for MG's popular TMC4500ST, MPC2000, Titan II and MetalMaster Plus plasma and oxyfuel cutting machines.

MG Systems and Welding, Inc. is known as the premier manufacturer of thermal cutting machines, using advanced plasma, laser, and oxyfuel cutting tools to cut shapes from metals. A full range of equipment is provided by MG Systems, with sales and service offices and dealers/distributors located throughout North America. MG Systems equipment is used in all types of manufacturing activities, including heavy duty equipment manufacturers, metal service centers, shipyards, job shops and fabricators.

Visit the MG Systems website at www.mg-systems-welding.com to see for yourself the productivity gains that are possible with MG Systems equipment or contact MG Systems and Welding, Inc. to learn how MG Systems can assist you with your plate processing needs. Phone 262-255-5520 or e-mail sales@messer-mg.com today.