Custom Substrates offer fast turnaround times.

Press Release Summary:

Direct Bond Substrates, using Curamik® DBC Ceramics, feature Ni, Ni-Au, and Pd plating finish for variety of power applications. DBC Substrates are available in 0.005, 0.008, and 0.012 in. copper thickness on Alumina and Aluminum Nitride cards sized 5.5 x 7.5 in. as multiple multiple-up master cards or as individual parts, after dicing or laser scoring. With turnaround times of ~3-4 weeks, prototype and low-volume production options are available from 5-card to 30-50 card packages.

Original Press Release:

Remtec® Adds Custom DBC Substrates Product Line Based on Curamik® Master Cards with Fast Turnaround

Norwood, MA Remtec Inc., the leading manufacturer of substrates and packages with Plated Copper On Thick FFilm (PCTFPCTF®) technology, has introduced a new line of Direct Bond Substrates using industry-proven Curamik DBC Ceramics and offering cost-effective prototype, low volume production and fast turnaround for a wide variety of power applications.

By combining the complimentary DBC and PCTF technologies from recognized industryrecognized industry leaders , Remtec is able to offer circuit and package designers a time- proven Curamik DBC substrates, combined with Remtec's mature plating technology and surface finish. In addition, the full capabilities of PCTF and DBC in the range of 0.0005"-0.012" copper are available. Remtec supports these technologies with a low volume manufacturing (LVM) program designed around standard lot sizes and select features with prearranged pricing. As a result, Remtec is able to offer custom DBC Substrates in low to medium volume with competitive pricing and fast turnaround.

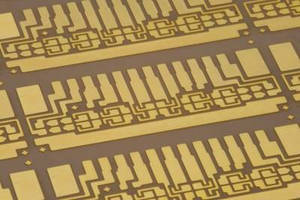

Remtec's DBC Substrates are available in nominal 0.005", 0.008" and 0.012" copper thickness on Alumina and Aluminum Nitride cards sized 5.5"x 7.5" as multiple multiple-up master cards or as individual parts, after dicing or laser scoring. Remtec offers DBC cards for prototypes and low volume production from 5 card packages to 30 50 card packages with turnaround time of approximately three to four weeks.

The performance characteristics of Remtec's DBC Substrates include mechanical strength and stability, high electrical isolation, high thermal conductivity, high current handling capacity, high power dissipation and low thermal resistance. In addition, copper finish options ensure excellent solderability and capability to withstand multiple soldering and brazing operations from 180 to 800oC without product degradation. Ni, Ni-Au and Pd plating finish permit economical assembly techniques including SMT soldering, low and high temperature die attach, Al and gold Au wire and ribbon bonding. For more information, go to www.remtec.com.

Typical applications for DBC Substrates include power semiconductors, telecommunications, power supplies, dc/dc converters, solar cells, automotive electronics, military, aerospace, defense, and industrial electronics.

Remtec, a RoHs compliant and 1S50 9001:2000 registered company, operates two manufacturing facilities totaling 30,000 sq. ft. in Norwood, MA. In addition to DBC products, Remtec provides custom and semi-custom packaging solutions using PCTF

technology for DC power electronics, optoelectronics, and MW/RF components and modules.