Custom Fluidization Products target powder handling industry.

Share:

Press Release Summary:

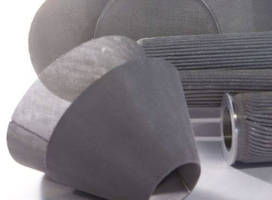

Sinterflo® stainless steel sintered mesh and Vyon® sintered porous plastics are materials that feature uniform porosity and ensure fluidization of powders without any dead spots. Degree of porosity and minimal pressure drops result in efficient use of energy to pump air. These free-standing powder fluidization solutions can be cleaned and custom manufactured to unique specifications, including flat beds, cones, and domes that will fit most assemblies.

Original Press Release:

Powder Handling Industry Turns to Porvair's High Performance Fluidisation Materials

An international leader in high performance filtration and separation is able to offer the powder handling industry one of the largest ranges of fluidisation technologies available from any single manufacturer.

Porvair Filtration Group is a specialist in designing, developing and supplying high end porous materials for the fluidisation of powders across a range of production processes, including pharmaceuticals, food, beverage and construction.

Agriculture and industrial chemical processing has also benefitted from Porvair’s innovative experience and unique know-how.

The fluidisation of powders, using compressed air through a porous media to make them flow like liquids, has a range of uses, such as the efficient emptying of silos, and road and rail tankers.

Porvair’s high performance range of Sinterflo® stainless steel sintered mesh and Vyon® sintered porous plastics offer customers optimum powder fluidisation solutions.

All of its materials are of uniform porosity and ensure the fluidisation of powders without any dead spots.

Furthermore, Porvair’s materials exhibit high porosity and low pressure drops that result in highly efficient use of energy to pump air.

They are also free-standing and robust, and unlike conventional canvas stainless steel mesh structures, can be easily cleaned.

Porvair – which has supplied the process industry with performance-driven filtration equipment for over 25 years – is proud to be able to custom manufacture to unique specifications, including flat beds, cones and domes that will fit most assemblies.

It manufactures in both the UK and USA and has an extensive network of sales offices and distribution channels throughout the world.

The company’s Market Manager Roy Rigby said: “It’s great to see our solutions having an impact across a diverse range of processes, meeting the high end needs of key industries.

“High porosity, low pressure drops, and avoidance of dead spots combine to make our materials a strong performer under any circumstance.

“We believe that the movement of such powders as drugs, flour and cement has never been easier, while the process of emptying silos, road and rail tankers, has attained unrivalled efficiency.

“Sinterflo® and Vyon® are at the heart of this sustained progression, and we are pleased to offer them for optimal powder fluidisation results.”