Conductive Adhesive targets die-attach applications.

Share:

Press Release Summary:

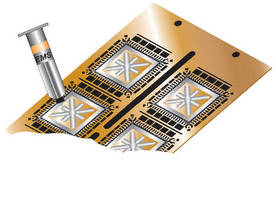

Able to cure in 30 minutes at 80°C or in seconds at 200°C, CA-180 Low Temperature Cure/Snap Cure Conductive Adhesive has optimized rheology for needle dispensing by time-pressure, auger, or positive displacement. After curing for 30 minutes at 80°C, electrical conductivity is 0.00006 Ω-cm. Product is suited for die-attach applications in smart cards, circuit assembly, photonics, and camera modules.

Original Press Release:

Engineered Material Systems Debuts Low-Temperature Cure/Snap Cure Conductive Adhesive for Die-Attach Applications

DELAWARE, OHÂ – Engineered Material Systems, a leading global supplier of electronic materials for circuit assembly applications, introduces the CA-180 Low Temperature Cure/Snap Cure Conductive Adhesive designed for die-attach applications in smart cards, circuit assembly, photonics or camera modules.

ECM CA-180 will cure in 30 minutes at 80°C or in seconds at 200°C, and has a moderate glass transition temperature (Tg) and modulus. CA-180 has an optimized rheology for needle dispensing by time-pressure, auger or positive displacement. Unlike most conductive adhesives, CA-180 develops excellent conductivity with short, low-temperature cures. After curing for 30 minutes at 80°C, its electrical conductivity is 0.00006 ohm-cm.

CA-180 is the latest addition to Engineered Material Systems’ extensive line of electronic materials for semiconductor, circuit assembly, photovoltaic, printer head, camera module, disk drive and photonic applications.

For more information about the CA-180 Low-Temperature Cure Electrically Conductive Adhesive or to learn how Engineered Material Systems can define, develop and create an engineered material solution that is right for your company, visit www.emsadhesives.com.

About Engineered Material Systems

Engineered Materials Systems, Inc. (EMS) technology focus is on electronic materials for semiconductor, circuit assembly, photovoltaic, printer head, camera module, disk drive and photonics assembly product lines. The company creates continual improvements that will guide its customers into the future. For more information, visit www.emsadhesives.com.