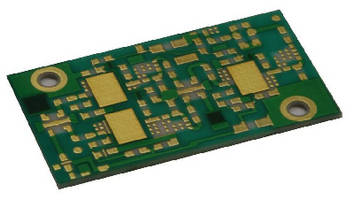

Ceramic Substrates support SMT soldering and die attach.

Press Release Summary:

Consisting of electroless nickel and immersion gold plating over thick film silver, AgENIG® Substrates eliminate solder leaching, enable processing up to 260°C or higher, assure optimal solder connections, and allow multiple SMT reflow solder cycles as well as touch-up and repairs. Addition of thin layer of Palladium plating also allows welding, gold wire bonding, and eutectic die attach. In addition, products based on metallization process can be used up to 170°C continuous operating temperature.

Original Press Release:

Remtec's New Proprietary AgENIG Ceramic Substrates

Norwood, MA – Remtec, the leading manufacturer of substrates and packages with Plated Copper on Thick Film (PCTF®) metallization, has developed and commercialized a proprietary process that resolves the metallization adhesion and long-term reliability problems caused by using RoHS compliant, lead-free solder alloys processed at high temperature. Remtec’s proprietary process replaces commonly used expensive thick film gold/platinum/palladium materials with much lower cost thick film processing.

Remtec’s use of AgENIG® (electroless nickel and immersion gold plating over thick film silver) reduces prices by at least half as compared to commonly used Pd-Pt-Ag-Au substrates. In addition to cost saving, Remtec’s AgENIG substrates offer significant performance advantages when using new lead-free, higher temperature solder required for RoHS compliance. The AgENIG process eliminates solder leaching and enables processing up to 260°C or higher, assures more robust solder connections, and allows multiple SMT reflow solder cycles as well as touch-up and repairs. Equally important, substrates and packages utilizing Remtec’s proprietary process also result in much better adhesion strength and higher long term reliability required by the most stringent military specs.

Remtec’s AgENIG substrates are suitable for various assembly types including SMT soldering and die attach. The addition of a thin layer of Palladium plating (Universal Finish) also allows welding, gold wire bonding and eutectic die attach. In addition, products based on this metallization process can be used up to 170°C continuous operating temperature. Pattern definition can be held to .006” line and spaces. The major characteristics of Remtec’s PCTF technology – multilayers, integrated resistors, plugged via holes, and plated thru holes – are also available with the new, proprietary process.

A combination of performance advantages, lower pricing, multiple assembly options, increased reliability and elevated operating temperatures make Remtec’s AgENIG substrates an important solution to the increasing demands of military, microelectronics, power electronics, oil exploration, and automotive applications.

Remtec, a RoHS compliant and ISO 9001:2008 certified company, operates a manufacturing facility totaling 33,000 sq. ft. in Norwood, MA. Remtec provides custom and semi-custom packaging solutions for DC power electronics, optoelectronics and RF/MW products in commercial, industrial and military industries.