CAE Software features integrated preplanning.

Share:

Press Release Summary:

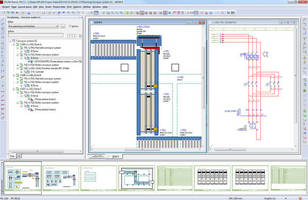

Supporting direct processing of comprehensive preplanning tasks, Eplan Platform v2.3 provide functions that increase project quality and data consistency while simultaneously reducing configuration expense. Central dialogue is preplanning navigator; defined segments for preplanning are displayed and administered within project. Use of preplanning macros and copying and moving existing segments by drag and drop accelerates and facilitates creation and editing of machine/plant structures.

Original Press Release:

Eplan Platform 2.3: Preplanning Built In

Preplanning and detail engineering are project phases which belong together. But they are traditionally processed using different systems. Now Eplan is integrating them. Preplanning is anchored into the system with the new Eplan Platform 2.3. Innovative functions increase project quality and data consistency, and at the same time reduce configuration costs.

Monheim - Preplanning is a decisive phase in the engineering process. It involves developing concepts for technical machinery/plant design and estimating initial volumes of project data. The new Eplan Platform 2.3 breaks new ground in this "key phase" for innovative designs. Whether it is graphical overviews, placeholders for functions, initial project data for drives, sensors and PLC inputs/outputs, or parts lists for calculations - comprehensive preplanning tasks can be processed directly in the Eplan Platform. The subsequent enclosure production and detailed design of the system is based on this comprehensive data - without new data entry or transfer from other systems. Users can benefit from very easy entry into this new planning method based on the Eplan Platform. This additional integration allows you to increase data consistency and project quality. At the same time, it reduces the cost of the project development process.

An overview of structures and data

The central dialogue in the Eplan Platform is the new preplanning navigator. In this dialogue, the defined segments for preplanning are displayed and administered within the project. The use of preplanning macros, and copying and moving existing segments by drag and drop, makes it quick and easy to create and edit machine/ plant structures. Alternatively, the CAE software has the option of working directly in the graphical editor for preplanning. The data defined at the preplanning stage can be outputoutputted in report form and used, for example, for parts lists or for calculating prices and labour. The process is integrative. Based on the preplanning in the navigator, the next phase of configuration involves deriving and producing the detailed plan, i.e. the schematic, using drag & drop. As a further alternative for data entry, the preplanning option incorporates a comprehensive import functionality allowing data to be exported into Eplan from Excel spreadsheets. This means that information from other planning departments can be taken into consideration. Using the import function preplanning structures can also be generated automatically.

Background:

The engineering process for a machine/plant involves individual phases in which the initial rough drafts and ideas for the design are gradually refined and made more specific until all of the documents and information required for production and construction of the machine are in place. Preplanning and basic engineering are the very early project phases in which concepts for technical machinery/plant design are developed and initial volumes of project data estimated. The aim is to determine the most technically apt design and define the guidelines for subsequent detailed planning (detail engineering). To date, the tasks of preplanning have often been processed in separate systems such as graphic tools, text processing systems for specifications or tables and databases, with only very basic or no interfaces to the configuration tool. This lack of data consistency and, often, a lack of support from engineering functionalities in these systems added up to considerably more work and poor quality at the configuration phase.

EPLAN Software & Service develops engineering solutions, which accelerate the product development process. Interdisciplinary expert systems assure the highest degree of productivity and data integration. The solution provider develops customer-specific and tailor-made PDM and PLM concepts and provides comprehensive services such as customizing, consulting and training. Innovative development competence, a consistently practical approach, and international presence are the resulting success factors. EPLAN is part of Rittal International and thus of the Friedhelm Loh Group with 11,500 employees worldwide and generated revenues of about 3 billion USD in 2011. EPLAN is therefore synonymous with continuity and investment security. Eight offices in North America and company presence in 50 countries support 35,000 customers with 95,000 installations worldwide. The corporate motto - 'Efficient Engineering' - underlines the proficiency of optimized, efficient processes, which keep companies competitive in the long term.

EPLAN Software & Services LLC

37000 Grand River Ave., Suite 380

Farmington Hills, MI 48335

USA

Christine KNAPIK

Phone: +1-630-408-3863

Fax: +1-248-945-9210

Knapik.c@eplanusa.com