Boundary Scan Module facilitates DDR3-DIMM socket testing.

Press Release Summary:

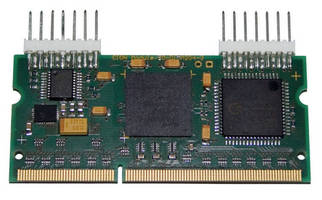

Once plugged into test socket, CION Module SO-DIMM204-3/ECC allows structural test coverage of DDR3 memory interfaces. All signal pins, as well as almost all Ground-Pins, can be tested via Boundary Scan. Equipped with CION™ Boundary Scan ASIC, module can be connected to any Test Access Point (TAP) and lets user detect link failures. Tests take fractions of seconds, and even parallel testing of multiple memory interfaces is possible.

Original Press Release:

GOEPEL Electronics Simplifies Test of DDR3-DIMM Sockets

GOEPEL electronics has developed a new solution for Boundary Scan test of DDR3-DIMM sockets. The CION Module SO-DIMM204-3/ECC is simply plugged into the test socket and allows the structural test coverage of DDR3 memory interfaces. All signal pins as well as almost all Ground-Pins can be tested via Boundary Scan. Equipped with the GOEPEL electronics Boundary Scan ASIC, CION™, the module can be connected to any Test Access Point (TAP). It enables the user to detect link failures, for example caused by incorrectly soldered pins or bent terminals.

In combination with the Boundary Scan software SYSTEM CASCON™, a comprehensive automation of the entire project development is possible. The module offers a simple, safe and inexpensive solution for test of complex DDR3 memory interfaces with minimal effort. Test time only takes fractions of seconds and even parallel testing of multiple memory interfaces is possible.

The CION SO-DIMM204-3/ECC modules can be used both in the laboratory for prototype test as well as in series production.

About JTAG/Boundary Scan:

Boundary Scan (IEEE Std. 1149.x) is a modern access method for the test and programming of complex circuits without mechanical probe access (non-intrusive).

Boundary Scan is part of the Embedded System Access (ESA) strategies and is based on design-integrated test electronics. ESA technologies include techniques such as Chip Embedded Instruments, Processor Emulation Test, In-System Programming or Core Assisted Programming. They are currently the most modern strategies for validation, test and debug as well as programming of complex boards and systems. They can be applied throughout the entire product life cycle, enabling enhanced test coverage at reduced costs.

About GOEPEL electronic:

GOEPEL electronic is a worldwide leading vendor of innovative electronic and optical test and inspection systems, being the market leader for professional JTAG/Boundary Scan solutions for Embedded System Access (ESA). A network of branch offices, distributors and service partners ensures the global availability of the products as well as the support of the more than 8,000 system installations. Founded in 1991 and headquartered in Jena/Germany, GOEPEL electronic employs currently more than 200 employees and generated a revenue of 25 Million Euro in 2013 (ca. $34 Mio). GOEPEL electronic has continuously been ISO9001 certified since 1996 and has been honoured with TOP-JOB and TOP-100 awards for being one of the best medium-sized companies in Germany. GOEPEL electronic’s products won several awards in recent years and are used by the leading companies in telecommunication, automotive, space and avionics, industrial controls, medical technology, and other industries. Further information about the company and its products can be found on the internet at www.goepel.com.