3D Measurement System excels at semiconductor applications.

Share:

Press Release Summary:

Able to work with transparent and shiny materials, HORUS can measure volume and dimensions of virtually any type of substance, part, component, or die, including very small features. FOV and inspection speed allow use of this system as as in-line inspection machine. Able to precisely measure transparent objects at production speeds, system can be used for full range of electronics manufacturing and assembly applications, including board-level SMT.

Original Press Release:

Koh Young Unveils New HORUS 3D Measurement for Semiconductor Applications at SEMICON West 2014

San Francisco, California, USAÂ – Koh Young Technology and Koh Young America will effectively enter the Semiconductor market with the unveiling of HORUS, Koh Young’s exciting new high-powered 3D measurement system, at SEMICON West in San Francisco. This innovative new inspection system, featuring breakthrough technologies, will be exhibited in Booth #5544 in the North Hall at the Moscone Center.

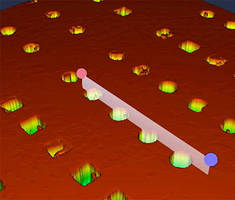

Koh Young’s groundbreaking HORUS, like the ancient Egyptian god it is named for, commands unexpected capabilities and special powers. For example, HORUS can measure the volume and dimension of virtually any type of substance, part, component, die, including very small features, very quickly and with astonishing accuracy. HORUS can also precisely measure transparent and shiny materials with high speed and accuracy, something that no other inspection systems currently available can do.

HORUS will help customers realize higher yields in Semiconductor and Advanced Packaging applications by measuring objects that have been considered difficult to measure with appreciable speed, without sacrificing accuracy. But HORUS boasts speed faster than any other inspection machine out in the market today. HORUS’ primary advantage over current systems is that HORUS can measure virtually any object, and is particularly capable of precisely measuring transparent ones at production speeds. HORUS is the first machine with this capability to enter the market.

HORUS excels at Semiconductor applications, but it is ideal for the full range of electronics manufacturing and assembly applications including board-level SMT. HORUS can measure shiny objects including flux and solder balls using its very wide Field of View (FOV) optics. The combination of wide FOV and quick inspection speed allows HORUS to be used as an in-line inspection machine.

This will also facilitate lot testing on all products, rather than traditional sampling inspection due to slow inspection speeds.In addition to the new HORUS, Koh Young will demonstrate its other patented full 3D Measurement- based inspection solutions for AOI applications in booth #5544. Koh Young's patented technology enables inspection based on the 3D profilometric shape of semiconductor components in flip chip packaging at in-line speed.

About Koh Young Technology

Koh Young Technology specializes in the design and manufacturing of 3D measurement and inspection equipment for the global circuit board assembly and semiconductor markets. Direct sales and support centers are located in the United States, Germany, Japan, Singapore, China and Korea. For more information about the company, visit www.kohyoung.com.