3D Vision Software Tools enhance automation applications.

Press Release Summary:

Delivering real-time, 3D position information, 3D-Locate(TM) enables automation equipment to work with variety of parts, including items that are stacked or tilted. Multiple sets of 2D features, found by PatMax® geometric pattern matching tool, are used to determine object's precise 3D orientation. Calibration tools further enhance performance by adjusting for optical distortion and camera position as well as synchronizing cameras with moving elements.

Original Press Release:

Cognex Offers 3D Vision Software

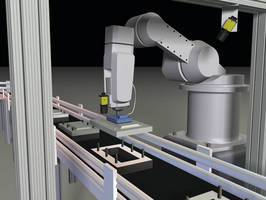

Cognex Corporation (NASDAQ: CGNX) announces 3D-Locate(TM), a library of 3D vision software tools that expands application possibilities in vision-guided robotics, assembly, and inspection.

Cognex 3D-Locate delivers accurate, real-time, three-dimensional position information that enables automation equipment to work with a wider variety of parts, including items that are stacked or tilted. Using 3D-Locate can improve vision performance for challenging applications such as logistics, robot-guided de-palletizing and precision assembly, and it can eliminate the need for expensive mechanical fixtures or measurement devices. Cognex 3D-Locate can also be used in combination with Cognex code reading, gauging, and inspection tools.

Robust 3D Location

Cognex 3D-Locate uses multiple sets of two-dimensional features found by Cognex's patented geometric pattern matching tool, PatMax®, to determine an object's precise three-dimensional orientation. PatMax tolerates non-uniform lighting and remains reliable even when patterns are partly covered, ensuring accurate part location even in the most challenging settings and conditions. Cognex 3D-Locate can also use input from other Cognex location tools such as SearchMax(TM) and PatFlex® to help determine part orientation.

Application performance is enhanced by high-precision Cognex calibration tools that adjust for optical distortion and camera position, and synchronize cameras with moving elements like robot grippers-key to the success of any 3D application. PC-based 3D-Locate can handle high throughput applications, and users have the option to choose from a wide range of industrial cameras.

"Many 3D vision packages fail to meet customer expectations in the field because the systems cannot deliver reliable, repeatable results," said Markku Jaaskelainen, Executive Vice President and Business Unit Manager for Vision Software. "With 3D-Locate, Cognex has leveraged more than a decade of experience in 3D applications to create a robust, general purpose tool that can be used for a wide variety of applications."

3D-Locate can be used in:

3D-Locate is available as part of the Cognex CVL software library. For more information on 3D-Locate, download a data sheet at www.cognex.com/3D.

About Cognex

Cognex Corporation designs, develops, manufactures, and markets machine vision sensors and systems, or devices that can "see." Cognex vision sensors are used in factories around the world to automate the manufacture of a wide range of items and to assure their quality. Cognex is the world's leader in the machine vision industry, having shipped more than 500,000 machine vision systems, representing over $2.5 billion in cumulative revenue, since the company's founding in 1981. In addition to its corporate headquarters in Natick, Massachusetts, Cognex also has regional offices and distributors located throughout North America, Japan, Europe, Asia, and Latin America. Visit Cognex on-line at www.cognex.com/.

For Reader Service Inquiries:

Tel. (Toll Free): 1-877-COGNEX1 (1-877-264-6391) Internet: www.cognex.com