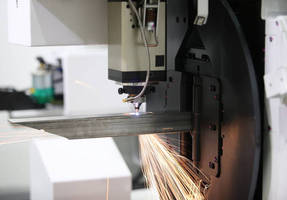

2D Laser Cutting Machine supports high-speed operation.

Press Release Summary:

Available with 2.5 or 4 kW resonator, TUBE GEAR can process round and rectangular tube and pipe with diameters up to 6 in., has standard 5 in. Servo Focus torch, and can make cuts at rapid traverse rate of up to 6,299 ipm. Triple chuck system minimizes warp and material vibration, allowing accurate, high-speed processing of material up to 21.3 ft long, while bundle material load/unload system increases throughput for lot sizes up to 4.2 tons. Automated calibration function is standard.

Original Press Release:

Mazak Introduces 2d Tube Gear for High-Speed Tube & Pipe Cutting

Elgin, Illinois — Mazak Optonics Corp. has released a new TUBE GEAR 2D laser-cutting machine with industry-leading processing speeds for tubes and pipes. The TUBE GEAR’s high-speed capabilities for thin-walled applications offer increased efficiency and a significant reduction in cost per part compared to similar tube and pipe cutting systems.

Available with a 2.5kW or 4kW resonator, the TUBE GEAR can process round and rectangular tube and pipe with diameters of up to 6 inches. It has a standard 5” Servo Focus torch and can make cuts at a rapid traverse rate of up to 6,299 IPM.

The TUBE GEAR is equipped with a triple chuck system which minimizes warp and material vibration, allowing for high-accuracy and high-speed processing of material up to 21.3’ long. It also includes a bundle material load/unload system which allows for increased throughput for large lot sizes up to 4.2 tons while still comprising a smaller footprint than similar machines.

Other standard features of the TUBE GEAR include an automated lens focal distance measurement system, automated calibration function and a nozzle cleaning system.

There is also an optional automated nozzle change system to significantly reduce machine set-up times.

About Mazak Optonics

Mazak Optonics Corporation is a major supplier of laser-cutting systems, offering 50 laser models and leading the industry in the implementation of emerging laser technologies. The company’s 50,000 sq. ft. North American Headquarters are located in Elgin, Illinois, and feature a 30,000 sq. ft. laser technology center housing up to 18 machines for demonstrations and training. Mazak Optonics is part of Yamazaki Mazak Corporation (Oguchi, Japan), the global leader for the manufacture of machine tools and systems for the precision machining of metal parts, including CNC turning centers, horizontal and vertical machining centers, Multi-Tasking machining centers, turnkey cells and software solutions. The North American Headquarters for Yamazaki Mazak are located in Florence, Kentucky. For more information on Mazak Optonics’ products and solutions, visit www.mazakoptonics.com, email sales@mazaklaser.com or call 847.252.4500.