Ink Viscosity Controller retrofits to sealed cup pad printers.

Press Release Summary:

Model VC-1 continuously monitors ink viscosity inside sealed ink cup. If viscosity varies outside preset range, solvent is automatically added to bring ink back to proper viscosity, without operator intervention. Unit mounts directly in ink cup, eliminating need for off-printer ink reservoirs. Model VC-1 works with single or 2-component inks.

Original Press Release:

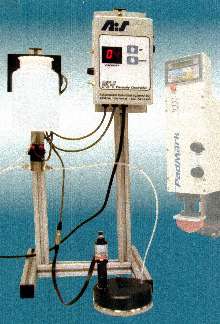

VC-1 Ink Viscosity Controller

Retrofits to Most Sealed Cup Pad Printers

For Immediate Release

Friday, July 25, 2003

Contact: Tonia D. Frank

Automated Industrial Systems, Inc.

814-838-2270

Erie, PA-AIS announces the latest advancement in pad printing technology-the VC-1 Viscosity Controller. The VC-1 continuously monitors ink viscosity inside a sealed ink cup. If the viscosity varies outside a preset range, solvent is automatically added to bring the ink back to the proper viscosity-without operator intervention or production interruption. Because the ink is automatically kept at the proper viscosity, production and quality are both increased.

The VC-1 can be retrofitted to most sealed cup pad printers. It is mounted directly in the ink cup eliminating the need for off-printer ink reservoirs, which allows for easy clean-up and color changeover. The VC-1 works with single or two component inks.

For more information on the VC-1 and our complete line of pad printing equipment, contact us at 814-838-2270.

For additional information, please contact Automated Industrial Systems. 4238 W. 12th Street, Erie, PA 16505 814-838-2270 E-mail: info@padmark.com