Viscom to Showcase Advanced SPI, X-ray and 3D AOI Portfolio at SMTAI

Duluth, GAÂ — Viscom announced today that it will exhibit in Booth #434 at SMTA International, scheduled to take place Sep. 30 - Oct. 1, 2014 at the Donald Stephens Convention Center in Rosemont, IL. Viscom’s inspection experts will present the most advanced and comprehensive SPI, AOI and X-ray portfolio on the market. The 3D function for Viscom’s AOI high-performance camera module XM is the latest step in the company’s continual improvement of the 3D performance spectrum.

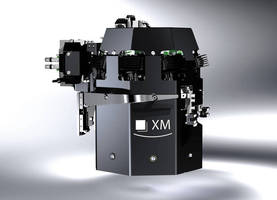

3D AOI XM camera module

Viscom’s XM module will be displayed with the addition of a structured light projector to the existing orthogonal and angular cameras, totaling more than 60 Megapixels. With an image acquisition rate of up to 1.8 gigapixels/second, the new XM module is extremely fast with simultaneous image acquisition. Its 3D inspection is up to four times faster compared to other systems with multiple projectors and consecutive imaging.

S3088 ultra with 3D XM camera module

The existing S3088 platform, with newly designed mechanics, and the addition of the 3D XM module, offers the fastest inspection speed with the best defect detection capability.

Further improvement of maintenance and service features allow reliable and economical machine operation. The addition of 3D AOI inspection to the new S3088 ultra presents a future proof inspection system for all AOI tasks conceivable today.

Conformal Coating Inspection - CCI

The new Viscom S3088 Conformal Coating Inspection (CCI) system inspects coatings quickly and reliably for typical defects such as cracks, bad spots, layers that are too thin or too thick, smearing, impurities or splashes. The Viscom S3088 CCI system features an 8M camera module equipped with UV LEDs that reveal visible light emitted by UV fluorescent indicators contained in the transparent protective coating. The S3088 CCI system is available immediately.

Quality Uplink

In SMT electronic assembly production, 3D SPI has established itself as the additional inspection point to complement optical or X-ray inspection. The key task is detecting unacceptable paste deposits in terms of volume, form, smearing and offset. In addition to providing defect detection, the Viscom 3D SPI can accomplish much more. The SPI-AOI-Uplink function links paste inspection and post-reflow inspection results for both easy and effective process control as well as improved classification of AOI results.

About Viscom

Viscom AG manufactures and sells high-quality automatic optical and X-ray inspection systems. The company is one of the leading suppliers of 3-D solder paste inspection, component placement and solder joint inspection equipment in the PCB assembly market. Viscom systems ensure quality in surface mount technology production lines, where they can be interlinked to further improve productivity. The company’s headquarters and manufacturing operation is located in Hanover, Germany. With a wide network of branches, applications and service centers, Viscom is represented throughout Europe, Asia and the Americas. Founded in 1984, Viscom has been listed on the Frankfurt Stock Exchange (ISIN: DE0007846867) since 2006. For more information, visit www.viscom.com.