Viscom Presents the Most Advanced and Comprehensive Range of High-speed 3D AOI, SPI and AXI Inspection Systems at Nepcon South China

Hanover, Germany –Â Viscom announced today that they will present the most advanced and comprehensive SPI, AOI and X-ray portfolio on the market in Booth #A-1C36 at Nepcon South China, scheduled to take place August 26-28, 2014 at the Shenzhen Convention Exhibition Center in China.

Viscom S3088 AOI and SPI systems are designed to flexibly cover even the most challenging requirements, from small series production to high-volume/low-mix. The new XM-3D camera module allows for especially fast inspections, with both high-resolution angled views and 3D analyses. Viscom’s all new FastFlow transport optimizes throughput and shortens cycle times.

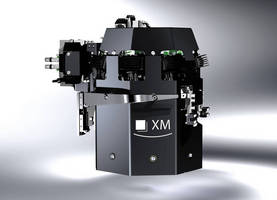

3D AOI XM camera module - high-speed 3D inspection

To meet current and future requirements in electronics manufacturing, not only must the inspection object as a whole be reliably detected, but each individual point of the object as well. This task is now solved in the XM module with the addition of a structured light projector to the existing orthogonal and angular cameras, totaling over 60 Megapixels. With an image acquisition rate of up to 1.8 gigapixels/second, the new XM module is extremely fast, and fully upgradeable for 3D.

Fastflow - new high-speed handling

Due to synchronous input/output of electronic assemblies, Viscom’s all new high-speed transport facilitates trouble-free and extremely fast changeovers in as little as two seconds. Even extreme cycle time requirements can be fulfilled effortlessly.

Quality Uplink - efficient process control

In SMT electronic assembly production, 3D SPI has established itself as the additional inspection point to complement optical or X-ray inspection. The key task is detecting unacceptable paste deposits in terms of volume, form, smearing and offset. In addition to providing defect detection, the Viscom 3D SPI can accomplish much more. The SPI-AOI-Uplink function links paste inspection and post-reflow inspection results for both easy and effective process control as well as improved classification of AOI results.

Process Uplink offers three major advantages for production:

First, an easier classification and prevention of human error and false calls by display of the AOI-SPI defect image pairs. Second, higher yield at the print process enabled by the additional display of SPI borderline defects at the AOI verification station. Third, direct process monitoring and improvement regarding paste print and solder defects.

About Viscom

Viscom AG manufactures and sells high-quality automatic optical and X-ray inspection systems. The company is one of the leading suppliers of 3-D solder paste inspection, component placement and solder joint inspection equipment in the PCB assembly market. Viscom systems ensure quality in surface mount technology production lines, where they can be interlinked to further improve productivity. The company’s headquarters and manufacturing operation is located in Hanover, Germany. With a wide network of branches, applications and service centers, Viscom is represented throughout Europe, Asia and the Americas. Founded in 1984, Viscom has been listed on the Frankfurt Stock Exchange (ISIN: DE0007846867) since 2006. For more information, visit www.viscom.com. Â