Standards-compliant Clean Green Plastic Cribbing Sets Benchmarks for Weight-bearing Consistency When Stabilising Heavy Loads

Share:

A new generation of recycled plastic cribbing system tested to be consistent with internationally recognised Australian Standards is being introduced throughout the Asia-Pacific.

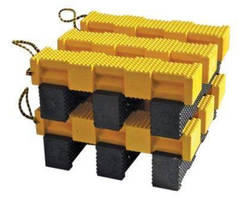

The lightweight, splinter-free, non-absorbent and environmentally sustainable Dura Crib ranges of blocking and cribbing products from the Cribbing and Matting Co have been engineered for maximum durability and tested under the guidance of AS1170 to ensure optimum safety and risk management when stabilising heavy loads.

"We believe this compliance is a first for high-performance plastic cribbing and a major safety benefit. Unlike other cribbing or blocking products, the Dura Crib range has a published Working Load Limit so users can safely and confidently use do their jobs without the worry of wondering if their blocking system is up to the job. This sets a new benchmark of quality, high performance and consistency of supply for safety-conscious industries," says Cribbing and Matting Co Pty Ltd Managing Director Mr Tony Brooks.

Such safety assurance, risk management and established continuity of supply is widely sought by industries dealing with heavy loads, such as mining and energy, oil and gas, construction and building, rescue and recovery, food processing, manufacturing and materials handling, industrial maintenance and safety, road and rail transport, ports and shipping and water, waste water and infrastructure.

Within the Dura Crib range there are blocks suitable for supporting weights of up to 110,000kg with a choice of high visibility yellow or ultra strength black.

• High-visibility safety yellow, with Working Load Limit of 36kg/cm2 at 25°C

• Ultra-strength, optimum performance black, with Working Load Limit of 60kg/cm2 at 25°C

Both types feature a globally proven, consistent and repeatable formulation with a 50-year warranty against splitting, rotting, absorption, termites and mould.

The lightweight, splinter free, high performance Dura Crib range was developed to replace older, weaker wood cribbing systems (below) with constant cracking and varying and unpredictable load-bearing capabilities.

"The use of wooden cribbing is declining in many industries throughout Australasia and South-East Asia," says Mr Brooks. "Not only is wood impossible to authenticate for Working Load Limit, but also wooden cribbing requires ongoing replacement involving extensive handling, consumption and disposal of a finite resource.

"In addition to wastage of scarce hardwoods, there are disposal problems with tons of wooden cribbing that soaks up oil, chemicals and hazardous waste products that abound on maintenance, fabrication and worksites. Such hazardous substances contained in waste wood cannot be dumped into landfill, where they can find their way into the water tables of rural and urban communities."

Dura Crib systems have been extensively proven under some of the world’s toughest safety regimes in the United States of America. A major advantage of Dura Crib is that it is a complete system of integrated products that can be combined to provide comprehensive solutions across a wide range of industries. Dura Crib offers complete solutions and continuity of supply for particular applications, rather than piecemeal product ranges and erratic availability.

Benefits of the re-engineered plastic cribbing and blocking systems include:

• Working Load Limit for confidence and safety in use

• Splinter free, reduced risk of injury

• Outstanding strength – Ultra strength, black, ranges are stronger than oak, with high stability and repeatability

• 100 per cent recycled plastic construction for optimum durability and environmental sustainability

• Resistant to gas, oil, chemicals and organic substances such as blood

• Laboratory tested, with consistent repeatable formulation and performance

• Suitable for both active cribbing, where a person is working nearby, and for passive cribbing, where cribbing is used to keep material off the ground to allow a forklift to operate.

"This is a truly durable and sustainable system, whereas the only guarantee with wood is that you will eventually have to replace it," said Mr Brooks.

"Dura Crib provides an engineered and easily handled system and is the fastest way to stabilise loads, including machinery and vehicles ranging from cars to heavy trucks. By ensuring stability quickly and easily in all industrial situations, it saves time and money and protects workers."

Ball valve stabilisation, left, and fork lift stabilisation, right

Rail car maintenance, left and hi-rail stabilisation centre and right

Crib stack, left, and machinery stabilisation

Fast stabilisation with step chocks, left and easy extrication with cribbing wedges, right

About Cribbing and Matting Co

Cribbing and Matting Co specialises in Cribbing and Matting. We fill a gap in the market, as most firms only sell these products as "add ons" to whatever else they may be selling. Cribbing and Matting is what we do, so at Cribbing and Matting Co our name says it all.

The majority of our diverse product portfolio is sourced from Turtle Plastics located in the USA. Turtle Plastics has earned the reputation of being at the forefront of recycling technology. For in excess of 30 years, Turtle Plastics has manufactured premium products used in the rescue, mining, construction, rail, marine, transport and defence industries, to name but a few.

Our mission is to create value for our customers by delivering innovative safe products, by being customer focused, as well as being market, technology and innovation driven. At Cribbing and Matting Co we are passionate about our products and our customers. We recognise that industry is looking for innovative alternatives to timber cribbing. With the ongoing debate about global warming and greenhouse gases, why would we cut down trees when using recycled plastic helps solve two problems in one? It cuts down on waste going in to landfill and helps us leave trees where they should be, green and growing.

Our matting solutions are also manufactured from recycled plastic and the range of styles and colours is sure to have something to suit most applications. Being modular means that you are not limited to particular sizes or shapes, you simply order the amount of tiles you require, and lay them in any shape to suit the requirements of you particular project.

Cribbing and Matting Co is conveniently located at Seven Hills in Sydney Australia. We take pride in providing the highest quality products and service. Call or email us to see how we can assist you with a cribbing or matting solution.

For more information, please contact:

Mr Tony Brooks

Managing Director, Cribbing and Matting Co

Unit 9

12 Abbott Road

Seven Hills, NSW 2147

ph 61 2 9674 7428

fax 61 – 2 9674 2724

Tony.b@cribandmatco.com.auwww.cribandmatco.com.au