Small Motor Stack and Coat Service Permits Smoother and Tighter Wire-Winding

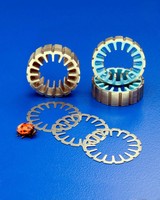

A stacking, laminating and coating service for small motors, stators and gyroscopes that permits smoother, more densely populated wire-winding is being offered by Applied Plastics Co., Inc. of Norwood, Massachusetts.

Applied Plastics' Stacking, Laminating, and Coating Service holds lamination alignment to within ±0.0005" and includes deburring and selective coating from 0.002" to 0.005" thick in one pass, to meet MIL specs. Permitting smoother and tighter wire-winding for motors, stators, and gyroscopes,

this service helps prevent wire cuts and shorts, resulting in less scrap.

Producing parts with electrical resistance up to 1,000 V/mil, depending upon configuration, Applied Plastics' Stacking, Laminating, and Coating Service is suited for parts from 3/8" to 8" O.D. Typical coatings offered include epoxy, PTFE Teflon®, and Heresite® nylon.

Applied Plastics' Stacking, Laminating, and Coating Service is priced according to part configuration, coating and quantity. Price quotations are available upon request. This service offers manufacturers one completed part, fully inspected, with one SKU number; ready for subsequent processing.

For more information contact:

Applied Plastics Co., Inc.

David Ring, Marketing

25 Endicott St. / P.O. Box 128

Norwood, MA 02062

(781) 762-1881 FAX (781) 769-3349

e-mail: davering@appliedplastics.com

www.appliedplastics.com