New Inspection Technologies for Higher Product Quality and Safety

Bosch expands inspection portfolio

• KHS 1: new high-end headspace leak detection platform from Bosch

• AIM 3 reliably combines visual inspection and high-voltage leak detection

• Cooperation with Lighthouse Instruments for best-in-class container closure integrity testing

Frankfurt/Main, Germany – At Achema 2015, Bosch Packaging Technology showcases two new pharmaceutical inspection machines. The KHS 1 is a new development emerging from a cooperation of Bosch with Lighthouse Instruments, LLC. It is designed for container closure integrity testing of ampoules, vials, bottles, cartridges and syringes using laser headspace analysis (HSA). The AIM 3, in turn, is the new member of the well-established AIM series. It offers the possibility to perform both visual inspection and high-voltage leak detection (HVLD) for ampoules and vials on one single platform. "These new platforms underline the expertise of Bosch Packaging Technology in all inspection areas. Independent of the product or application, we can offer extensive consulting and the appropriate technology to ensure the highest product safety and quality for all requirements," Mahmoud Hamada, business development manager at Bosch Inspection Technology, explains.

Successful cooperation with HSA pioneer

To further expand its inspection portfolio, Bosch collaborated with Lighthouse Instruments, the leading provider of non-destructive laser spectroscopy headspace analysis systems. This expertise in leak detection fits ideally with the highest quality requirements of the pharmaceutical industry. "By combining this expertise with our market-leading machinery for pharmaceutical inspection applications, we have developed a highly flexible and customizable high-speed platform," says Joachim Baczewski, head of Inspection Technology and president of Bosch Packaging Technology K.K. in Japan. Jim Veale, president of Lighthouse Instruments, adds, "We are excited to offer the pharmaceutical industry best-in-class leak detection machines together with Bosch PackagingTechnology."

The KHS 1 is the new high-end leak detection system from Bosch for closure integrity testing with laser headspace analysis. It measures the absorbed light passing through the headspace region via laser spectroscopy. HSA is applicable to lyophilized products and medicines filled under vacuum or purged with inert gas. The new KHS 1 inspects both standing and non-standing containers at outputs of up to 600 per minute, and can combine HSA with optional near infrared (NIR) measurement and container coding. In order to ensure the highest reliability and accuracy, a built-in automatic re-calibration is continuously performed using certified reference containers.

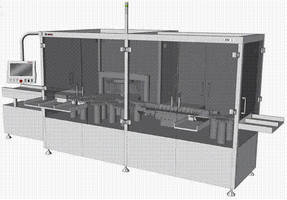

AIM 3: compact platform for visual inspection and leak detection

Eisai Machinery (now Bosch Inspection Technology) developed the first model of the AIM series forty years ago. In 1985, the successful KLD series using HVLD technology was introduced. It detects leaks by measuring the electrical resistance of containers with conductive solutions. At Achema, Bosch now launches the new AIM 3, which combines both visual inspection of the AIM series and high-voltage leak detection of the KLD series. It inspects ampoules and vials containing solutions and suspensions at outputs of up to 400 containers per minute. "Our aim was to offer pharmaceutical producers and contract manufacturers from all over the world an economical solution for medium speeds at high Bosch quality standards," Mahmoud Hamada explains.

In order to sort out damaged containers before they enter the main inspection turret, the AIM 3 is equipped with a pre-inspection station. The core module features a high-resolution CMOS camera with high-speed interface for particle and cosmetic inspection, as well as a re-inspection function. The customizable platform can be retrofitted on site to add further visual inspection stations or the HVLD module. The latter delivers equivalent measurement results for all glass qualities, such as molded and tubing, as well as clear and amber glass. Both inspection steps are controlled via one common Human Machine Interface (HMI). Bosch's technologies are on display at Achema in Frankfurt/Main, Germany, from June 15 to 19, hall 3.1, booth C71.

Press photo: 1-PA-21156, 1-PA-21157

Contact: Contact person for press inquiries:

Mahmoud Hamada Christin Poenisch

phone: +49 7951 402-1620 phone: +49 711 811-58502

Based in Waiblingen near Stuttgart, Germany, and employing 5,600 associates, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology. At over 30 locations in more than 15 countries worldwide,  highly-qualified workforce develops and produces complete solutions for the pharmaceuticals, food, and confectionery industries. These solutions are complemented by a comprehensive after-sales service portfolio. A global service and sales network provides customers with local points of contact. Additional information is available online at www.boschpackaging.com

The Bosch Group is a leading global supplier of technology and services. It employs roughly 360,000 associates worldwide (as per April 1, 2015). The company generated sales of 49 billion euros in 2014.* Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology.

The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including its sales and service partners, Bosch is represented in roughly 150 countries. This worldwide development, manufacturing, and sales network is the foundation for further growth. In 2014, Bosch applied for some 4,600 patents worldwide. The Bosch Group's strategic objective is to create solutions for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is "Invented for life."

Additional information is available online at www.bosch.com, www.bosch-press.com,

http://twitter.com/BoschPresse

*The sales figure disclosed for 2014 does not include the former joint ventures BSH Bosch und Siemens Hausgeräte GmbH (now BSH Hausgeräte GmbH) and ZF Lenksysteme GmbH (now Robert Bosch Automotive Steering GmbH), which have since been taken over completely.

Robert Bosch GmbH

Postfach 10 60 50

D-70049 Stuttgart

E-mail Christin.Poenisch@bosch.com

Phone +49 711 811-58502

Fax +49 711 811-58509

Corporate Communications,

Brand Management, and Sustainability

Senior Vice President: Dr. Christoph Zemelka

www.bosch-press.com