New Fully Variable Hydraulic Valve Control System Cuts CO2 Emissions by up to 25 Per Cent

A collaborative development between the Schaeffler Group and Fiat Powertrain has resulted in a groundbreaking new engine system, the world's first fully variable hydraulic valve control system.

A groundbreaking system for automotive power transmission systems has been launched, which reduces vehicle fuel consumption and cuts CO2 emissions by up to 25 per cent.

UniAir, a joint development between the Schaeffler Group and Fiat Powertrain, is a unique fully variable hydraulic valve control system that will make its debut on Fiat's new Alfa MiTo 1.4 MultiAir. This is the first vehicle within the Fiat Group to be equipped with this innovative technology.

As well as offering car manufacturers a more compact valve control system, UniAir will help the automotive industry meet future CO2 emissions targets for passenger cars. UniAir provides improvements in start-up, part load and acceleration behaviour of the vehicle. During the engine warm-up phase, for example, hydrocarbon (HC) emissions are up to 40 per cent less, and nitrogen oxide (NOx) is reduced by up to 60 per cent. In addition, UniAir offers a greatly improved driving experience through more power, higher engine torques and optimised engine response.

Car manufacturers will be particularly impressed by the fact that UniAir enables car engines to be downsized. Fiat uses UniAir in its four-cylinder FIRE series of engines and in its small volume two-cylinder engines that are currently being developed. As well as petrol engines, UniAir will also be available for diesel engine applications.

Developed for series production by Schaeffler, UniAir refers to the system as MultiAir. This name follows the style of the MultiJet CommonRail direct diesel injection system, which was also initiated by Fiat. UniAir/MultiAir is also based on an invention by the Centro Ricerche Fiat (CRF). The takeover of the license in 2001 marked the beginning of successful development collaboration between Fiat and Schaeffler, culminating in series production and market launch. In 2003, the first functioning prototype was developed. Further prototype vehicles were manufactured two years later.

The final design specification was completed in 2007 and manufacturing facilities for series production started at various Schaeffler Group locations in 2008. MultiAir has been in development for Fiat and Alfa Romeo since May 2009.

"The development of the fully variable valve control system to production standard has involved complex efforts in the fields of mechanics, hydraulics and valve control software," explains Michael Haas, Director Advanced Engineering and Business Development at Schaeffler Group Automotive's Engine Systems unit. A 45-strong development team undertook these tasks.

How it works

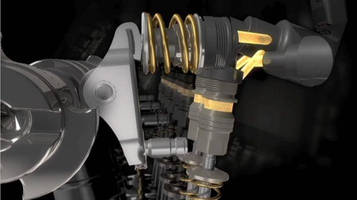

UniAir is a cam-actuated, electro-hydraulic valve train system. The fully variable valve control can be used for both petrol and diesel engines and is supplied via the existing engine oil circulation system. For petrol engines, UniAir enables throttle-free, continuously variable, software-based load control across the entire engine map. With diesel engines, regulation of the temperature of the combustion chamber is achieved due to the precise control of exhaust gas recirculation rates. At the same time, the effective compression ratio in the cylinder can be varied and a homogeneous combustion ensured.

For the first time, UniAir allows not only variations in the valve stroke, but also in the opening and closing of valves several times during one cycle, at different points in time. Therefore, the system significantly expands the potential of traditional valve train mechanisms.

UniAir can provide full coverage of every conceivable airflow possibility, from zero lift to maximum lift, dictated by the camshaft lobe for each individual cylinder or valve. With the de-throttling of the engine, UniAir can provide early intake-valve closing or late intake-valve opening in order to maximise engine breathing relative to certain engine speed and load conditions. UniAir offers unique valve lift events for every valve - individually and cycle-to-cycle. In contrast, an electromechanically actuated, fully variable valve train requires several cam events to achieve the same lift differential.

"UniAir is the beginning of a new era in valve trains and therefore in technology, producing engines that are eco-friendly and dynamic at the same time," commented Dr Peter Pleus, Executive Vice President of Schaeffler Group Automotive.

For more information on UniAir, please visit www.schaeffler.co.uk or telephone the marketing department on 0121 313 5870.

The Schaeffler Group is among the innovation leaders in Germany with around 1,250 patent applications annually. With its brands INA, LuK and FAG, it is a renowned supplier to the automotive industry as well as a leading manufacturer of rolling bearings worldwide. Around 66,000 employees generated sales of approximately 8.9 billion euros in 2008. The automotive industry represents around 60 per cent of Schaeffler sales.

The Schaeffler Group is a renowned development partner to the industry with system expertise for the entire drive train. Precision products for engines, transmissions and chassis applications ensure reduced energy consumption and lower emissions as well as increased driving comfort and safety. In addition to classic manual transmissions and automatic transmissions, the Transmission Systems Business Division offers automated manual transmissions, dual-clutch transmissions and CVTs. The range of transmissions for the future is rounded off by applications for alternative drive concepts such as hybrid drives. Schaeffler Automotive Aftermarket supplies distributors and independent workshops with replacement parts and services.

Dean Palmer

Director

SilverBullet PR Ltd

Tel: 01780 753 000

Mobile: 07703 023 771

Email: dean@silverbulletpr.co.uk

www.silverbulletpr.co.uk

Schaeffler (UK) Ltd,

Forge Lane

Minworth

Sutton Coldfield

West Midlands B76 1AP

Tel: 0121 351 3833

Fax: 0121 351 7686

e-mail: info.uk@schaeffler.com

www.schaeffler.co.uk