Negri Bossi Takes Two Energy Saving Integrated Production Units to Fakuma

Share:

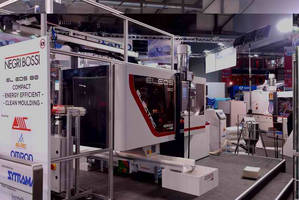

Leading injection press maker presents the two-platen ELEOS model with clean room for moulding of liquid silicone for medical applications and the JANUS hybrid with side entry robot.

Two complete integrated production units to showcase two great new developments: this is how Negri Bossi aims to make its mark at Fakuma 2012, the international plastic processing industry fair to be held in the German city of Friedrichshafen from 16th to 20th October. Our participation at the event is particularly significant this year as the company has recently decided to invest in the German market by putting Herbert Gegenheimer - who comes from a background in plastic moulding presses and has extensive technical and commercial experience - in charge of promoting and selling its plants. The organisation headed by Herbert Gegenheimer is situated in southern Germany and enjoys support from a technical assistance service.

On the first of the two units on the stand, Negri Bossi will be showcasing the low-consumption, two-platen ELEOS electric press for medical applications. One of the most compact in its category, this 80-ton press has a fully electric injection unit that carries out liquid silicone moulding for medical applications. Platen clamping/opening is also electrically powered. A hydraulic control unit with an inverter-equipped servomotor-driven system provides power for the core and ejector movements. The integrated production unit comes complete with an incorporated cartesian Sytrama robot and a clean room that will be used at the fair to produce, for demonstrative purposes, feeding bottle teats.

The second integrated production unit will be dedicated to packaging. Here, visitors will get the opportunity to see a 220-ton JANUS class hybrid press in action, with handling being carried out by a side entry Sytrama robot. This unit stands out on account of IML technology - developed jointly by Negri Bossi and Sytrama - which allows the production of items in which the decorative label is perfectly incorporated in the plastic material. Like the ELEOS, the JANUS is marketed with a strong focus on its outstanding energy saving performance, a feature now shared on all new-generation Negri Bossi presses.

These two units perfectly encapsulate just how much Negri Bossi has achieved through efficient synergy with Sytrama, the leading Italian automation firm taken over by the Cologno Monzese-based company last year.

The BI-POWER, which was developed in Imola and draws on SACMI's decades of experience in large-scale presses, an area in which the brand is market leader, has been placed on the local market via a series of initiatives aimed at generating steadily growing interest within the automotive sector. Unparalleled experience in the international motor vehicle industry has made several customisations and supplementary features available on the VH series, all of the very highest standard. Complete production units recently installed in customers' factories highlight the outstanding technology of the Division's know-how and, via the showcase offered by this key German fair, paint a picture of direct competitiveness that is on a par with local manufacturers.