MD&M East: RAUMEDIC, the Single Source Provider for Polymer Tubing, Molding and Assembly

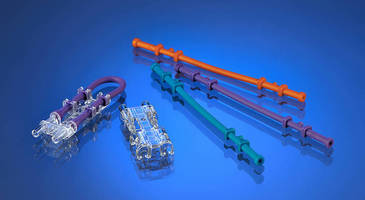

Leesburg, NCÂ — RAUMEDIC is a development partner and system supplier for polymer products for the medical technology and pharmaceutical industry. At MDM East in New York, the company presents the newest innovations from the world of polymers. Thermoplastic PTFE Moldflon tubing, unique silicone molding parts and innovative catheter systems will be the highlights at booth 1245.

As a special feature RAUMEDIC presents its latest developments in the field of silicone injection molding with the slogan "Silicone Intelligence Inside". From June 9 to 11, 2015 RAUMEDIC introduces innovative solutions for medical and pharmaceutical silicone products with complex requirement profiles at their MDM booth 1245.

Using pump segments as an example, RAUMEDIC informs the visitor about the world of silicone. High dosage accuracy represents an important criterion in medical engineering. The tubing and molded parts used need to fulfill tightest tolerances. This applies to pump devices which are used in hospitals as well as in homecare. Fields of application include enteral feeding pumps and pain management pumps.

"Silicone Intelligence Inside – made by RAUMEDIC" enables a direct integration of functions. Connectors, fixing elements as well as pressure sensors and bubble detection areas can be integrated without any additional parts or further processing steps. A combination of silicone and thermoplastic parts in one system is also possible.

For primary packaging products, e.g. prefilled syringes, RAUMEDIC fulfills the specifications of the ISO 15378 also for silicone components. Product examples are stoppers for drug containers or syringes. Based on DIN EN ISO 9001, ISO 15378 specifies a large number of additional requirements, particularly for primary packaging materials that come in contact with drugs.

About RAUMEDIC:

RAUMEDIC AG is active worldwide as a development partner and producer for the medical technology and pharmaceutical industry, providing tubing, precision moldings and catheters as well as assemblies and systems. All thermoplastic polymers and silicones are processed to meet the quality requirements of medical devices. In addition, RAUMEDIC develops and produces high-precision pressure measuring systems with microchip technology for the specific indications of neuromonitoring, urology, and traumatology.

It is through its own research and development that RAUMEDIC provides highly-demanding customers with specific products. RAUMEDIC has a worldwide distribution network and operates in selected markets through its own companies.

With over 60 years of know-how in the fields of extrusion, molding and assembly, RAUMEDIC is best equipped to transform the ideas of their customers into fully developed product solutions. Its own compounding for customized material input and prototyping complete the portfolio.

Customer satisfaction and compliance with all relevant legal and official requirements are at the heart of RAUMEDIC'S approach to quality which is based on an ISO 13485 quality management system as well as in accordance with ISO 14644 (Class 7) clean room production requirements.

RAUMEDIC is investing 27.1 million US dollars to construct a new production center in the US. With the US headquarters with development center and clean room production in Mills River in North Carolina, RAUMEDIC provides its North American customers a local service center. The production will start there in January 2016 with more than 50 employees and increase this number gradually to over 100. Furthermore RAUMEDIC is already expanding its German headquarters in Helmbrechts, Bavaria at a cost of around 26 million Euro. This will create another 190 jobs in the upcoming years.

RAUMEDIC has a staff of about 600 employees. Further information may be found at: www.raumedic.com

Antje Kizina

Marketing Communications Manager

Raumedic, Inc.

+49 9252/359-1861

antje.kizina@raumedic.com