LPKF at NPE 2009 in Chicago

Share:

The Plastic Welding Division of LPKF Laser & Electronics AG (LPKF) presents two new developments to the U.S. market at NPE in Chicago: The laser welding system LQ-Vario and a device for laser staking.

Erlangen, Germany, May 11th 2009- At NPE in Chicago, LPKF will be demonstrating the new LQ-Vario, a flexible and compact laser welding system specially equipped for the economical processing of small and medium sized production volumes. Further applications are prototyping and process development. In addition, LPKF supports component suppliers with comprehensive expertise on materials, clamping, processing, and in-line technology. "We have a great deal of cutting edge experience with automotive and medical components. With the new LQ-Vario and the know-how of our Application Center, interested parties can quickly find solutions to set up their own reliable processes," says Frank Brunnecker, Manager of LPKF's Plastics Welding Division.

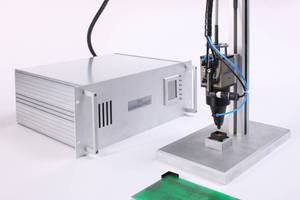

Laser staking is a new method for mechanically bonding two components. This patented technology is ideal for the fastening of electronic printed circuit boards in plastic housings. The method has similarities to laser plastic welding, and boasts the typical benefits of this technology. Its benefits include low mechanical stress on the joining parts, a small heat-affected zone, and high reproducibility. It is used wherever material-locking joints are needed between a thermoplastic component and another component, in a process that guarantees reliable production control.

In the South hall of McCormick Place (Booth S2040) customers will see the laser staking device in action. Additionally, LPKF will explain how easy it is to integrate their LaserQuipment® systems into existing automation solutions, and about the wide range of applications and advantages of the technology of laser plastic welding.

About LPKF

LPKF Laser & Electronics AG manufactures machines and laser systems used in the fabrication of electronics, automotive components, and in the production of solar cells. Around 20 percent of the workforce is engaged in research and development.

The Plastics Welding Division of LPKF Laser & Electronics AG develops, produces, and distributes equipment for laser plastics welding. Laser plastic welding techniques are gaining ground around the world especially in applications found in the automotive, medical and consumer goods sectors.

Contact:

Marika Nitscher

m.nitscher@lpkf.de

Tel. +49 (0)9131 61657-17

Fax +49 (0)9131 61657-77

LPKF

Laser & Electronics AG, Plastic Welding Division

Gundstr. 15

D-91056 Erlangen, Germany

www.laserquipment.com

LPKF Laser & Electronics North America

Plastics Welding Division

180 Engelwood Dr. Suite I

Orion, MI 48359 USA

Board of Managing Direc-tors:

Dr. Ingo Bretthauer (CEO)

Bernd Lange (COO)

Kai Bentz (CFO)

Shares:

Prime Standard

ISIN 0006450000