KLA-Tencor Extends Its 5D(TM) Patterning Control Solution with New Metrology Systems

Comprehensive Overlay and Films Process Control Solutions Address Advanced IC Process Challenges

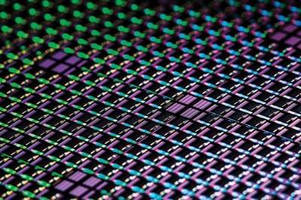

MILPITAS, Calif. — Today, KLA-Tencor Corporation (NASDAQ: KLAC) introduced two advanced metrology systems that support the development and production of 16nm and below IC devices: Archer™ 500LCM and SpectraFilm™ LD10. The Archer 500LCM overlay metrology system provides accurate overlay error feedback through all stages of the yield ramp, helping chipmakers resolve overlay issues associated with innovative patterning techniques, such as multi-patterning and spacer pitch splitting. Through reliable, precise measurement of film thickness and stress, the SpectraFilm LD10 films metrology system enables qualification and monitoring of the films and film stacks used in fabrication of FinFETs, 3D NAND and other leading-edge devices. The new systems are key products in KLA-Tencor's unique 5D™ patterning control solution, which drives optimal patterning results through the characterization and monitoring of fab-wide processes.

"As the industry leader in non-destructive optical metrology, we have closely collaborated with our customers to understand their challenges in optimizing pattern overlay, critical dimensions and films quality," stated Ahmad Khan, group vice president of KLA-Tencor's Parametric Solutions Group. "Across foundry, logic and memory, our customers require production-capable metrology systems that produce the data necessary to decipher complex process issues. Full-featured metrology systems, such as our new Archer 500LCM and SpectraFilm LD10 platforms, implement multiple innovations that facilitate measurement flexibility across a broad range of applications, helping our customers drive current-node yield and investigate next-node technologies."

With both imaging and unique laser-based scatterometry measurement technologies, the Archer 500LCM overlay metrology system offers a wide range of measurement options and supports a diverse range of overlay measurement target designs, such as in-die, small pitch and multi-layer targets. This flexibility enables cost-effective generation of accurate overlay error data that can be used for scanner corrections or for identification of inline excursions, helping engineers determine when to re-work wafers or adjust processes to meet strict patterning requirements. Multiple Archer 500LCM systems are in use at foundry, logic and memory manufacturers worldwide where they provide an independent assessment of overlay performance for advanced development and high volume production.

The SpectraFilm LD10 introduces a laser-driven plasma light source, producing reliable, high-precision film measurements for a broad range of film layers, including the thin, multilayer film stacks used in forming complex device structures such as FinFETs. Characterization of the thick, multilayer film stacks found in 3D NAND flash devices is enabled with a new infrared-based subsystem. With a significant increase in throughput compared to the previous-generation Aleris® platform, the SpectraFilm LD10 maintains high productivity while qualifying and monitoring the increased number of film layers associated with multi-patterning and other leading-edge fabrication techniques. Multiple SpectraFilm LD10 orders have been placed for use in advanced IC development and production.

The Archer 500LCM and SpectraFilm LD10 systems join the SpectraShape™ 9000 critical dimension and device profile metrology platform, K-T Analyzer® advanced data analysis system and many other process control systems in supporting KLA-Tencor's comprehensive 5D patterning control solution. To maintain the high performance and productivity demanded by leading-edge IC manufacturing, the Archer 500LCM and SpectraFilm LD10 systems are backed by KLA-Tencor's global, comprehensive service network. More information can be found on the 5D patterning control solution web page.

About KLA-Tencor:

KLA-Tencor Corporation, a leading provider of process control and yield management solutions, partners with customers around the world to develop state-of-the-art inspection and metrology technologies. These technologies serve the semiconductor, LED and other related nanoelectronics industries. With a portfolio of industry-standard products and a team of world-class engineers and scientists, the company has created superior solutions for its customers for more than 35 years. Headquartered in Milpitas, Calif., KLA-Tencor has dedicated customer operations and service centers around the world. Additional information may be found at www.kla-tencor.com (KLAC-P).

SOURCE KLA-Tencor Corporation

CONTACT:

Media Relations:

Meggan Powers

Sr. Director, Corporate Communications

(408) 875-8733

meggan.powers@kla-tencor.com

Web Site: www.kla-tencor.com