Juki's High-Speed Sentry Hits Triple Crown with EM Asia Innovation Award

MORRISVILLE, NC - Juki Automation Systems, a world-leading provider of automated assembly products and systems and part of Juki Corporation, announces that it has been awarded a 2012 EM Asia Innovation Award in the category of Pick-and-Place Systems - High-Speed for its Sentry System. The award was presented to the company during an April 26, 2012 ceremony in Shanghai during NEPCON China.

Established in 2006, the EM Asia Innovation Awards program strives to recognize and celebrate excellence in the Asian electronics industry, inspiring companies to achieve the highest standards and push the industry forward.

Juki Automation Systems' National Sales Manager Steve Nadeau commented on this accomplishment "The Sentry System is true embedded inspection in the assembly process. It allows products to be built right the first time and every time. Juki and CyberOptics are both excited to bring this new tool to the market, and we expect widening use in the years to come."

With the introduction of Sentry, Juki has integrated the inspection process into the assembly sequence. The Sentry System was developed in cooperation with CyberOptics Corporation and is the first system to prevent incorrectly assembled boards from being reflowed. Boards are inspected at each step of the placement process with innovative sensors allowing only correctly assembled boards to enter the reflow oven.

The system does not impact the speed of the line. When/if defects are found, they are shuffled off into a buffer and the line continues to run. Additionally, the system makes no-go decisions, resulting in no false calls and dramatically increasing throughput. The result is100 percent first-pass yields.

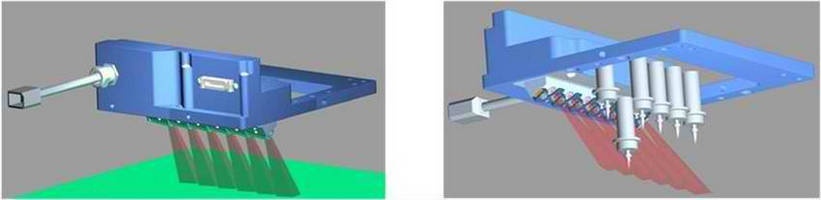

The Sentry features innovative sensors that monitor every step of assembly. The Embedded Process Verification (EPV) Placement Monitor consists of an array of micro-cameras equipped with strobing LEDs. The cameras record five shots of each pick-and-place sequence, providing root-cause failure analysis and allowing engineers to quickly diagnose any assembly problem. The Strobing Imaging Module (SIM) quality monitor photographs boards in segments and then combines them into one image. These sensors, combined with an integrated software package, make the Sentry the most powerful tool available in PCB assembly.

Juki, a global leader in high-speed SMT Assembly equipment, has shipped more than 25,000 machines worldwide since 1987. Juki has built its global image with a combination of top-quality and high-reliability machines with a reputation for world-class service and support that result in the lowest production costs for its customers. The pioneer of the modular assembly system in 1993, Juki offers flexible solutions designed for both high-volume and high mix environments.

Additionally, Juki Americas offers selective solder and stamp soldering machines backed by the largest field service group in the industry. For more information, visit www.jukiamericas.com

CONTACT:

Geron Ryden

Juki Automation Systems

507 Airport Blvd.

Morrisville, NC 27560

919-460-0111 x130

E-mail: GRyden@jas-smt.com

Web Site: www.jukiamericas.com