Intelligrated Offers Robotic Arm Retrofits to Existing Alvey In-Line Palletizers

Upgrade brings flexibility at a lower cost than a new robotic palletizing solution

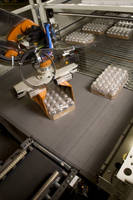

(Cincinnati: June 21, 2010) Intelligrated® (www.intelligrated.com), a leading North American-owned automated material handling solution provider, announces the launch of the Alvey® Robotic Retrofit Program for its family of Alvey in-line case palletizers. The program includes installation of one or more jointed-arm robots to create a hybrid palletizer that combines robotic flexibility and repeatability with the speed and reliability of conventional palletizer layer deposition. Benefits of the Alvey retrofits include gentler positioning and rotation of product, automatic line changeovers, pattern changing flexibility and extended operational life - at a lower cost than a new robotic palletizing solution.

Retrofits are completed on-site by removing the slat divider and existing case turners from the Alvey in-line case palletizer and installing one or two robotic arms for pattern forming. Intelligrated offers each customer a choice of robotic arm OEM and operating software. Every robotic retrofit includes design and manufacturing of end-of-arm tooling, OIT (Operator Interface Terminal) screens, infeed conveyor and PLC programming.

"Whether it is SKU proliferation, consolidation, environmental packaging concerns or 'labels out' pallet demand, flexibility has become more critical in recent years," said Frank Pellegrino, vice president, machine products, Intelligrated. "As marketing initiatives impact package size, shape and the amount of secondary packaging, pallet loads that traditionally rely on the product to build a strong unit load have become more susceptible to damage. The Alvey hybrid solution fulfills this need for gentler manipulation of containers with reduced packaging without compromising the integrity of the finished product."

Flexible pattern forming from the OIT allows operators to handle changing packages and multiple SKUs quickly and easily. Patterns can be programmed to orient high-graphic packaging, creating ready-to sell pallets quickly and easily. With quick product reconfiguration and instant line changeovers, the Alvey Robotic Retrofit achieves gentle packaging rates in excess of 100 cases per minute.

For sales and marketing information, please contact Emily Smith, senior marketing coordinator, Intelligrated, by phone at (513) 881-5239 or by e-mail emily.smith@intelligrated.com.

For media information, please contact

Samantha Devine,

public relations,

Koroberi, Inc.,

phone: (919) 945-0566

e-mail: samantha@koroberi.com.

About Intelligrated

Intelligrated® (www.intelligrated.com) is a leading North American-owned, single-point provider of automated material handling solutions with operations in the U.S., Canada and Mexico. Headquartered in Cincinnati, Intelligrated designs, manufactures and installs complete material handling automation solutions, including IntelliSort® line sortation systems, Crisplant® tilt-tray and cross-belt sortation systems, conveyor systems, Alvey® palletizers and robotics, Real Time Solutions® order fulfillment systems, warehouse control software and advanced machine controls-all supported by 24x7 Customer Service and Support.

Serving the warehousing, distribution, consumer product manufacturing, postal and parcel markets, Intelligrated collaborates closely with its clients to develop productivity solutions and responds to their needs throughout the life of their material handling systems.

Contact: Emily Smith

Company: Intelligrated

Phone: 513-881-5239

Fax: 513-881-5251

Email: emily.smith@intelligrated.com

www: www.intelligrated.com