FARO Laser Trackers Dominate Global Market

September 12, 2006, Lake Mary, FL- FARO Technologies, Inc., the world's single source for a complete line of portable CAM2 solutions, has officially established itself as the worldwide market leader in laser tracker sales.

The Company's next largest competitor's recent press release showed that they shipped more than 400 units in approximately three years. In that same time frame, FARO shipped over 600 Laser Trackers-outselling the other brand by 50 percent. The third-place competitor may have sold fewer than 75 in the same time period.

"Market demand is clearly shifting toward FARO Laser Trackers," FARO President and Co-CEO Jay Freeland said. "To date, sales continue to remain strong, and we are well on pace to produce our 1,000th unit by October 2006. This is a considerable achievement and testament to the growing reputation of the Tracker's state-of-the-art technology."

In addition to growing its market share in the automotive and heavy equipment industries, FARO logged major contracts with aerospace giants Boeing and Airbus, as well as their respective subsidiaries and OEM suppliers. Freeland credits the FARO Tracker's popularity with its unique features that increase productivity, including automatic warm-up and compensation routines. Also of benefit is the fact that FARO is the first manufacturer to conform to the ASME B89.4.19 Standard for laser tracker performance, and is the only manufacturer with an ISO-17025 accreditation based on this procedure.

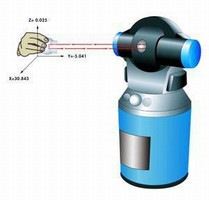

The FARO Laser Tracker is a portable, computerized measurement device that creates a 3-D "blueprint" of large objects and parts up object's entire surface, the Tracker emits a laser beam that is reflected back from the target, allowing the system's laptop computer to simultaneously draw and record all of its 3-D measurements with up to .001" accuracy. The Tracker can also take automatic measurements by steering the laser to multiple targets positioned on the object.

Engineers and designers use the data to reverse-engineer, improve or create new parts and products-or improve how they're made. Quality control personnel use it to verify that the parts have been made correctly, and, if not, where they need to be corrected.

The FARO Tracker's portability and advanced technology allow users to increase production efficiency while decreasing time-to-market, scrap, and re-work costs by measuring on the production shop floor, design room, or anywhere it's convenient.

For more information visit www.faro.com.

About FARO

With approximately 12,500 installations and 5,500 customers globally, FARO Technologies, Inc. (NASDAQ: FARO) and its international subsidiaries design, develop, and market software and portable, computerized measurement devices. The Company's products allow manufacturers to perform 3-D inspections of parts and assemblies on the shop floor. This helps eliminate manufacturing errors, and thereby increases productivity and profitability for a variety of industries in FARO's worldwide customer base. Principal products include the Platinum, Titanium, Advantage, and Digital Template FaroArms; the FARO Gage, Gage-PLUS and PowerGAGE; the FARO Laser ScanArm; the FARO Laser Tracker X and Xi; the FARO Laser Scanner LS; and the CAM2 family of advanced CAD-based measurement and reporting software. FARO Technologies is ISO-9001:2000 certified, and accredited to ISO-17025 Calibration Laboratory Standard.

Contact:

Darin Sahler

Global PR Manager

Email: Darin.Sahler@faro.com

Tel: 407-333-9911